Page 39

EN

Chapter 10 Maintenance

!

WARNING

Maintenance and cleaning work can put

the safety of operating staff at risk and impair the

functionality of the machine.

1. Before any cleaning and maintenance work, switch off

the machine pull out the mains plug.

2. Secure the machine against unexpectedly being

switched back on.

3. Before cleaning with the water jet, cover all the open-

ings that water must not penetrate into for safety and

functional reasons.

4. After cleaning, remove all the covers which were at-

tached to protect against the water.

10.2 Maintenance plan: Time and frequency

Maintenance work

Frequency/personnel

qualification

- Visual and functional

inspection of all safety

devices.

- Inspection of all wear parts,

conveyor hoses and coup-

lings.

- Visual Inspection of the

electrical cabling.

Daily by the

operator

Regreasing the sealing unit

Once a quarter

(recommended), or

for heavy use, once a

month by the operator.

Have the machine inspected

at a specialist workshop or at

an INOTEC service centre

Once a year

(recommended) by a

service technician

Electrical inspection (DGUV V3)

by a qualified electrician or at

an INOTEC service centre

Once a year (Mandatory,

stipulated by DGUV V3)

by a qualified electrician

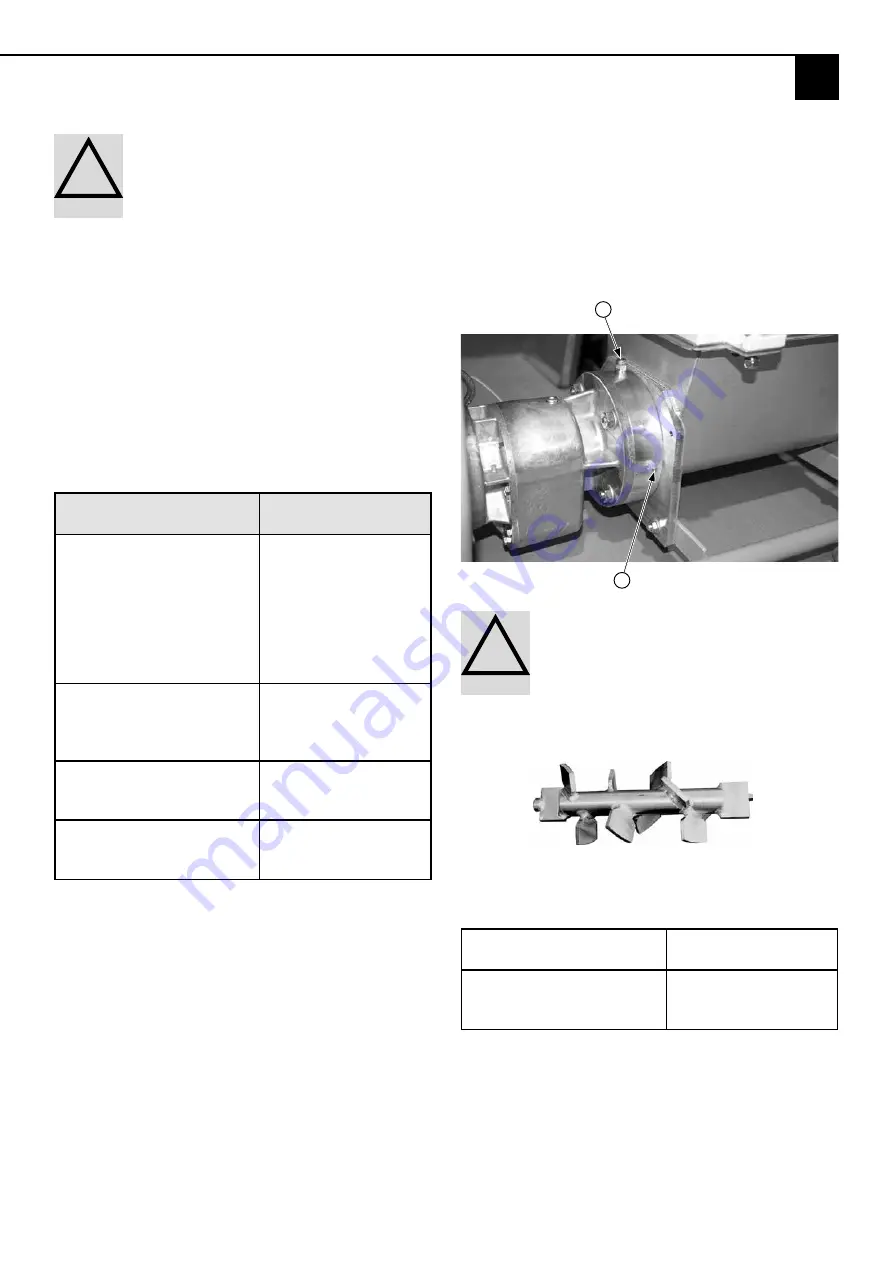

10.3 Regreasing the sealing unit

The sealing unit requires almost no maintenance. However,

it is necessary to regrease the seal’s depot every quarter, or

for heavy use, every month. If this maintenance measure is

not carried out or not carried out in time, the sealing rings

may run dry, causing the seal to fail prematurely.

1. Use a grease gun with roller bearing grease.

2. Press the grease into the grease nipple (1) provided until

excess grease comes out of the pressure relief valve (2).

1

2

!

CAUTION

The seal will become damaged if it is not

filled with grease

.

10.4 Wear limit for pump shafts

The pump shafts are subject to wear. The entire pump shaft

must be replaced if the minimum height of the augur blades

is reached or not reached.

Maximum height of augur

blades

38 mm

Wear limit:

Minimum height of augur

blades

30 mm

10.5 Wear limit for rotor/stators

The rotor and stator are wear parts that must be checked

regularly and replaced if necessary.