43

Use of ANSI / IEEE C37.06-1989, Rating of Power Circuit

Breakers under a Symmetrical Fault Basis

ANSI / IEEE C37.06-1989 can provide guidance for the

time of latch release and the duration of arcs for power

circuit breakers. The latch release time is approximately

the same time value as the main contacts parting, which

is required for the

A Input Delay

setting. This standard

addresses power circuit breakers with voltage ratings

from 13 kV to in excess of 500 kV. To be qualified as an

ANSI rated breaker, which most utilities use, the following

performance criteria must be met under symmetrical fault

conditions:

Breaker Voltage

M

UST

c

LeAR

T

IMe

(

TRIp

INITIATe

TO

ARc

exTINgUIShMeNTS

)

<230kV

3 cycles at 60Hz

>230kV

2 cycles at 60Hz

Table 6: Must-Clear Times of Breakers, Voltage Dependent

Note:

Pre-1989 breakers may not conform to this

standard. Always use manufacturers data or oscillographic

data if available.

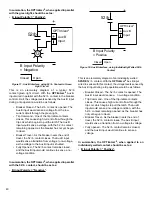

Figure 20: Estimated Trip Latch Release Times based on

Nameplate Breaker Voltage

Based on these limits, and using the assumption that

breakers are designed to clear a fault faster as the applied

voltage increases; the following timing graph is based

on ANSI C37.06-1989 for latch release times. These

approximations should be helpful to determine the A INPUT

DELAY setting when a time trace is unavailable, and the

OPTI

mizer

2

is being applied with the trip initiates (red light)

for the Aux A input assertion. These approximations may

also have use if the 52 / a contact of the breaker is being

used for the Aux A assertion, however, the time interval from

the trip initiate signal to the 52 / a contact opening must be

known. The breaker manufactures instruction literature or

original factory trip trace will provide useful information.

Contact Wear Mode

The

OPTI

mizer

2

can be programmed to use one of

two available Contact Wear modes,

I

x T

or

I

2

T

. In

I

2

T

mode, the square of the current measurement is used in

calculating contact wear units.

Note:

When the

OPTI

mizer

2

is cold-started, the Contact

Wear Mode is set to “

I

2

T

”.

To set the Contact Wear Mode, select the CONFIGURATION

tab and click “EDIT”: The Contact Wear Mode is selected

from a pull-down list.

Contact Life Danger Limit

The Contact Life Danger Limit is the alarm setpoint for

cumulative

I

x T

or

I

2

T

duty. This limit is usually correlated to

the ultimate wear-out of the contacts. Breaker manufacturers

typically provide nameplate data that supplies enough

information to calculate the Contact Life limit. Some breaker

nameplates do not supply all of the information required,

however, ANSI C37.06-1989 provides guidelines that can

assist in deriving ultimate duty wear estimates. The equation

used is:

Danger Limit = (N

F

)

I

(squared for

I

2

T)

•

T

, where

• N

F

is the rated number of fault interruptions,

• I

is the full rated fault current (Amps RMS symmetrical)

• T

is the arc time of the breaker.

Notice that it is only the

arc time

that is used in the

calculation, and not the total clearing time. The arc time is

used because it is during the arc interval that the heating

takes place, which degrades the breaker. During the current

carrying phase of clearing a fault, no arcing, and therefore

no heating takes place. The current carrying interval from

trip initiate to main contacts parting should not be included

in the wear limit calculation.

The required nameplate data are:

• Full fault (symmetrical) current capability (

I

). If this

value is not available, or if the breaker is rated in

MVA, see

Incomplete Nameplate Data

, addressed

later in this section.

• Number of times breaker can interrupt full fault

(symmetrical) current (N

F

). If this value is not

available, see

Incomplete Nameplate Data

,

addressed later in this section.

• The rated voltage of the breaker.

To arrive at the arc duration time of the breaker, which is

used for

T

, several methods may be used:

• Viewing of a recent oscillographic record of the

breaker clearing, noting the time from main contacts

parting to arc extinguishments, all phases.

• Using ANSI / IEEE C37.06-1989 as a guideline to

arrive at an arc duration estimate (see ANSI / IEEE

C37.06-1989, Figure 15, and Appendix B).

Note:

When the

OPTI

mizer

2

is cold-started, the Danger Limit

parameter is set to 0.1.