28

3.3 Description of SF

6

Density Monitoring

The

OPTI

mizer

2

monitors SF

6

gas density to aid in

identifying circuit breakers with potential problems.

Investigation and maintenance can be scheduled sooner,

keeping SF

6

gas loss to a minimum.

Density Loss

Power circuit breakers that use SF

6

gas as a dielectric can

lose gas from one or a combination of several causes.

Lost gas may adversely affect the dielectric capability for

extinguishing an arc, and consequently, the main contacts

by erosion (wear).

Gas Loss Causes

The following issues may cause problems leading to loss

of SF

6

gas:

• Gasket deterioration

• Shaft Seal deterioration

• Tank porosity

• Bushing porosity

• Tubing & pipe fittings

• Heater failure (allowing liquefaction)

Any of these may manifest themselves as a decrease in SF

6

gas density. Accompanying a loss of SF

6

gas density may

be a detectable increase in arc duration.

SF

6

Gas Monitoring

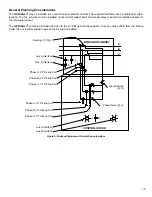

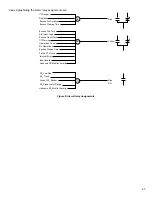

SF

6

Gas Density Sensors

The

OPTI

mizer

2

monitors

the signal from two types of SF

6

gas density sensors:

Analog (4-20mA) and Digital (INCON DSDP). Both types

are connected to the

OPTI

mizer

2

with two wires. The

OPTI

mizer

2

provides DC power to the sensors. The

Digital sensor will provide a temperature signal in addition

to the density signal.

The

OPTI

mizer

2

measures SF

6

gas density and

calculates SF

6

gas pressure from the measured

density. Pressure calculations are based upon

entered or calculated SF

6

gas volume and temperature

measurements. The Pressure Trend is calculated from the

Density Trend and temperature measurements.

SF

6

volume is calculated from entered nameplate gas fill

weight, pressure and temperature, or taken directly from

entered gas volume.

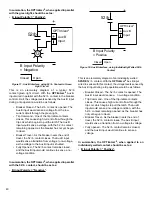

Low Gas Warning and Alarm

If the SF

6

gas density or pressure decreases, the

OPTI

mizer

2

will give a warning when a programmable

limit is reached. The SF

6

Alarm LED will light and a time-

stamped record of the warning will be logged in the history.

If the SF

6

gas density or pressure decreases further, a Low

Gas Alarm will be activated, closing the SF

6

Alarm Relay.

A time-stamped record of the alarm will be recorded in the

history log.

SF

6

Mass Loss Reporting

Once a day, the

OPTI

mizer

2

will calculate the change in

SF

6

mass. This value will be logged in the SF

6

History,

Daily Summary.

Density or Pressure Trends and Alarms

Once a day, the

OPTI

mizer

2

will compute density or

pressure trends for each active SF

6

input channel. Each

density or pressure trend is based upon measurements

collected over a 15-day time period. A Confidence Level

(%) will be associated with each of these trends, indicating

the number of valid readings each trend is based upon and

the stability of the readings. Fifteen days of valid readings

are required for 100% confidence in the computed Density

or Pressure Trend.

If the Density or Pressure Trend Alarm Limit is reached

or exceeded, the SF

6

Alarm LED will light, the SF

6

Alarm

Relay will close and a time-stamped record of the alarm

will be recorded in the history log.

Low Gas Alarm Forecast

Once a day, the

OPTI

mizer

2

computes the number of

days before the SF

6

gas will reach the Low Gas Alarm

Limit. This forecast will be based upon the Density or

Pressure Trends just computed.

SF

6

Gas Data Logging

Every 2 hours, the

OPTI

mizer

2

will log the present SF

6

gas density, pressure & temperature readings. Once a

day, the

OPTI

mizer

2

will log the average density, average

pressure, density or pressure trend, confidence level,

mass, change in mass and accumulated mass loss.

At any time, when a warning or alarm occurs, its

occurrence is recorded in the history log.