Installing the Tray

To install the Cable Management Tray in the selected rack:

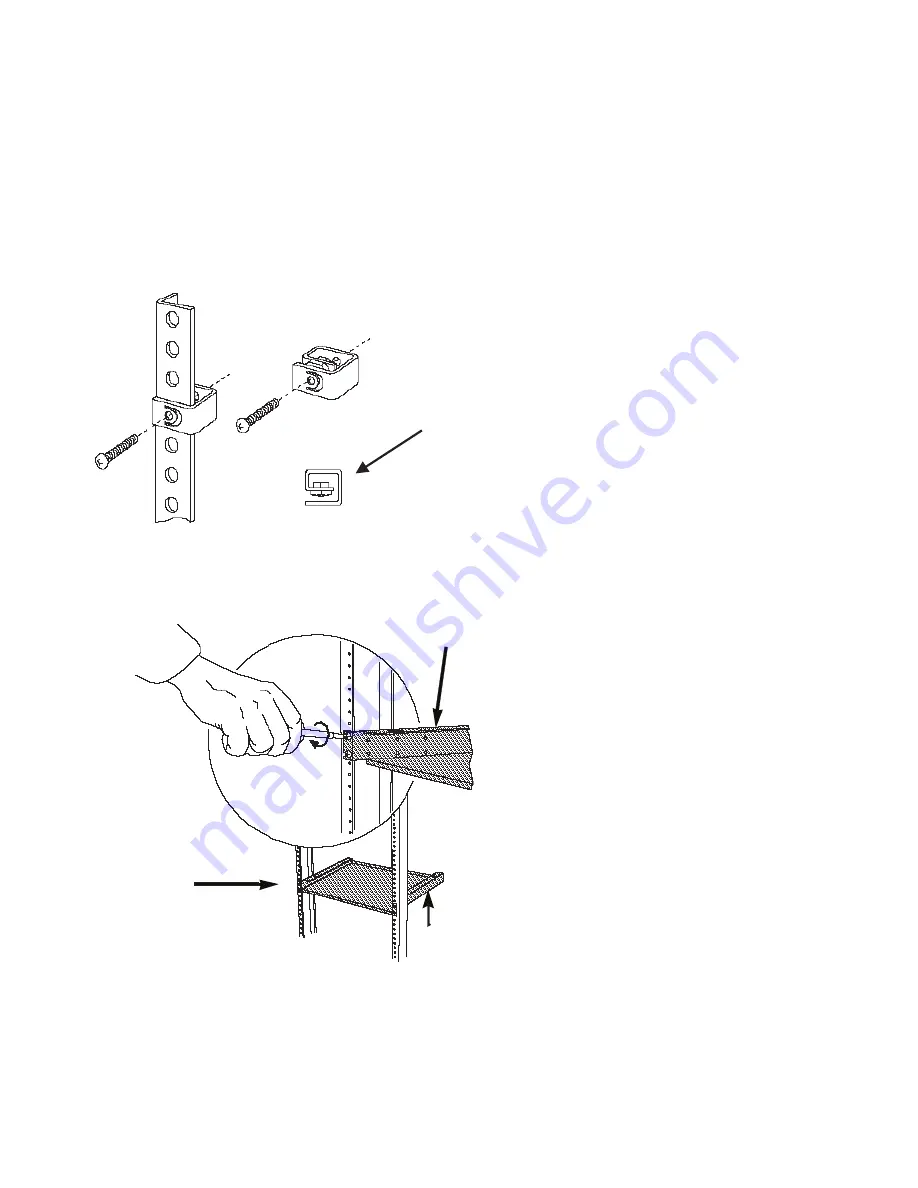

1. Attach the two rack mount flanges (supplied) to the Cable Management Tray using the flathead screws

provided (eight, 8-32 x 1/4-inch screws, four per side). Install the screws using a Phillips- head

screwdriver. Installed Cable Management Tray rack mount flanges are shown in Figure 4.

2. Install the clip nuts provided (four) onto the front of the rack at the position where the Cable

Management Tray will be attached. Figure 3 shows the clip nut installation.

Be sure to thread the screw

through this nut to securely

attach each clip nut to the rack.

Figure 3. Installing a Clip Nut in the Rack

Figure 4 shows the Cable Management Tray in the rack.

Installed rack

mount flange

Installed cable

management

tray

Installed rack

mount flange

Figure 4. Installing the Cable Management Tray in a Rack

3. Place the Cable Management Tray in the rack and attach the tray to the front of the rack using the

screws provided (four, 10-32 x 1/2-inch screws). Install the screws with a Phillips head screwdriver.

10

IBM 8265: Installation Guide

Summary of Contents for 8265 Nways ATM Switch

Page 1: ...8265 Nways ATM Switch IBM Installation Guide SA33 0441 02...

Page 2: ......

Page 3: ...8265 Nways ATM Switch IBM Installation Guide SA33 0441 02...

Page 8: ...vi IBM 8265 Installation Guide...

Page 10: ...viii IBM 8265 Installation Guide...

Page 12: ...x IBM 8265 Installation Guide...

Page 14: ...xii IBM 8265 Installation Guide...

Page 32: ...18 IBM 8265 Installation Guide...

Page 52: ...38 IBM 8265 Installation Guide...

Page 68: ...54 IBM 8265 Installation Guide...

Page 88: ...Models 17S Serial Number Located on the 8265 chassis label 74 IBM 8265 Installation Guide...

Page 98: ......

Page 101: ......

Page 102: ...IBM SA33 441 2...