|

8

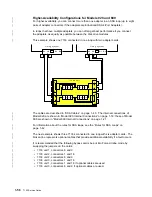

Check for continuity between the frame of the 7133 and the ground pins 1 and 7 of

|

the mainline-power connector.

P in 1

Pin 7

Pin 12

P in 6

|

9

If any fan-and-power-supply assembly has no continuity, exchange that

|

fan-and-power-supply assembly for a new one (see “Fan-and-Power-Supply

|

Assemblies” on page 3-32), then do the complete grounding check again.

|

If each fan-and-power-supply assembly has continuity, you might have a problem

|

with the power cables or with the grounding of the using system.

|

10

Check the power cables for continuity. Check between ground sockets 1 and 7 of

|

the plugs and the screw

6

.

P in 1

Pin 7

Pin 12

P in 6

1-66

7133 Service Guide

Summary of Contents for 7133 Series

Page 1: ...7133 SSA Disk Subsystems Service Guide SY33 0185 02...

Page 2: ......

Page 3: ...7133 SSA Disk Subsystems Service Guide SY33 0185 02...

Page 8: ...vi 7133 Service Guide...

Page 14: ...xii 7133 Service Guide...

Page 44: ...Labels Dummy Fan and Power Supply Assembly 1 30 7133 Service Guide...

Page 94: ...2 10 7133 Service Guide...

Page 110: ...2 2021 6 7133 Service Guide...

Page 114: ...2 2022 4 7133 Service Guide...

Page 138: ...2 2330 18 7133 Service Guide...

Page 146: ...2 16 7133 Service Guide...

Page 210: ...3 64 7133 Service Guide...

Page 222: ...4 12 7133 Service Guide...

Page 229: ......

Page 230: ...Part Number 32H6990 Printed in the United Kingdom 32H699 SY33 185 2...