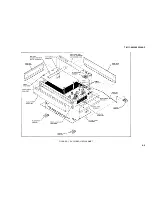

FIGURE 5-23. X-AXIS GEAR TRAIN BEARINGS

c.

Remove two clamps holding pulley housing. Slip

drive belt off pulley and pull assembly (A) out of its hold from

bottom. See Figure 5-23.

d.

Remove retaining ring from belt pulley shaft. Slide

shaft out of housing.

e.

Remove defective bearing(s) and replace with new

bearing, Part No. 1410-0277.

f.

Reinstall pulley. Adjust belt tension. See paragraph

5-76.

g.

Reassemble.

5-91. ELECTRICAL ADJUSTMENTS

5-92. GAIN ADJUSTMENT

5-93. The gain potentiometers are labeled GAIN on the control

panel and are adjustable wit a screwdriver. If gain in X or Y

channel is insufficient (poor retrace) adjust as follows:

a.

Connect low frequency Function Generator to X and

Y input terminals. Set up for triangular output wave of 500 mV

pk/pk at 0.1 Hz.

b.

Set X RANGE switch to 100 mV/in. (40 mV/cm), Y

RANGE switch to 1V/in. (0.4V/cm).

c.

Turn on recorder.

d.

Adjust R237 until minimum retrace error exists.

e.

Pen speed should not exceed 1 in./sec (0.4 cm/sec).

f.

Similarly, set Y RANGE switch to 100 mV/in. (40

mV/cm), X RANGE switch to 1V/in. (0.4V/cm).

g.

Adjust R137 for optimum retrace at 1 in./sec (0.4

cm/sec).

5-94. CALIBRATION ADJUSTMENT

5-95. If recalibration adjustment is required to accommodate

various graph papers, etc., perform the following procedure:

a.

Connect DC Standard to X input terminals.

b.

Set RANGE switch to 100 mV/in. (40 mV/cm).

c.

Adjust ZERO controls to position pen exactly at zero.

d.

Apply 1.0 Vdc (1.25V) signal to X input terminals.

e.

Adjust R226 to position pen to full scale.

5-14

Summary of Contents for HP-7035B

Page 1: ...TECHNICAL MANUAL HEWLETT PACKARD MODEL HP 7035B ...

Page 9: ...FIGURE 1 4 DIMENSION DRAWING FIGURE 1 5 ACCESSORIES 1 3 ...

Page 12: ...FIGURE 1 7 TYPICAL FREQUENCY RESPONSE INPUT FILTER FIGURE 1 8 TYPICAL DYNAMIC RESPONSE 1 6 ...

Page 14: ...FIGURE 2 1 WING BRACKET INSTALLATION FIGURE 2 2 STACKED CONFIGURATION 2 2 ...

Page 16: ...FIGURE 3 1 FRONT PANEL CONTROLS 7035B AND 7035B 001 MODELS 3 2 ...

Page 20: ...FIGURE 4 1 BLOCK DIAGRAM FIGURE 4 2 DETAILED BLOCK DIAGRAM 4 2 ...

Page 48: ...TM 11 6625 2850 14 P FIGURE 6 1 EXPLODED VIEW CABINET 6 9 ...

Page 49: ...TM 11 6625 2850 14 P FIGURE 6 2 EXPLODED VIEW CARRIAGE ARM SHEET 1 OF 2 6 10 ...

Page 58: ...FIGURE 7 1 COMPONENT IDENTIFICATION FRAME 7 8 ...

Page 59: ...TM 11 6625 2850 14 P Figure 7 2 Component Identification Circuit Board 7 9 ...

Page 60: ...TM 11 6625 2850 14 P Figure 7 3 Schematic Model 7035B D 07035 92550 7 10 ...

Page 62: ...TM 11 6625 2850 14 P FIGURE 8 1 COMPONENT IDENTIFICATION CIRCUIT BOARD 8 2 ...

Page 66: ...TM 11 6625 2850 14 P FIGURE 8 5 EXPLODED VIEW CARRIAGE ARM 8 6 ...