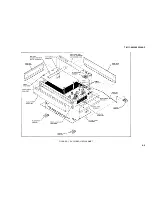

FIGURE 5-13. SLEWING SPEED DETERMINATION

FIGURE 5-14. X-AXIS SLEWING SPEED TEST SETUP

d.

Apply 1 VDC to X input at beginning of a Y excursion.

e.

Measurement is shown in Figure 5-13.

5-59. COMMON MODE REJECTION

5-60. DC REJECTION

a.

Set RANGE switch to 1 mV/in. (0.4 mV/cm). Connect

input terminals with short between high (+) and guard, and 1K

Resistor between low (-) and guard.

b.

Connect DC Standard between Y guard terminal and

ground.

c.

Set DC Standard to 500 volts.

d.

Pen will overshoot and settle to a level not It exceed

0.16 inch (4.0 mm) from initial position on chart.

e.

Repeat at all fixed attenuator positions for Y inputs.

f.

Repeat test for X-axis. Pen deflection is same.

CAUTION

Before removing input leads, reduce

signal to zero.

5-61. AC REJECTION

a.

Set RANGE switch to 1 mV/in. (0.4 mV/cm). Connect

the 1k ohm resistor between the high (+) and low (-) terminals,

and a short between the low (-) and guard terminals.

b.

Pen deflection shall not exceed 0.1 inch (2.54 mm)

with pen in any position on paper.

c.

Set Function Generator to 10 V peak-to-peak sine

wave and sweep frequency ±3 Hz around line frequency.

d.

Pen deflection shall not exceed 0.2 in. (5 mm) with

pen at any position on paper.

e.

Repeat at all fixed attenuator positions for Y inputs.

f.

Repeat test for X-axis. Pen deflection is same.

5-62. MECHANICAL ADJUSTMENTS

5-63. PROCEDURE

5-64. Any adjustment to the instrument is deemed necessary

only when it is determined the instrument is out of adjustment

per specifications, but not malfunctioning due to component

failure.

5-65.

Y-AXIS DRIVE STRING TENSION CHECK/

ADJUSTMENT

5-66. The Y cable tension may be verified by measuring the

force required to move the pen carriage downscale while the

motor is locked. This required force shall be between the limits

of 6 ounces and 12 ounces. To perform the procedure, it is

necessary to first remove be rear hood and platen. The

procedure is shown in Figure 5-15.

5-67. If the string tension is not correct, the string must be

lengthened or shortened to attain the desired tension. This

can be accomplished by removing the pen block from the pen

arm and retying the knot on the end of the string. See

paragraph 5-42.

5-9

Summary of Contents for HP-7035B

Page 1: ...TECHNICAL MANUAL HEWLETT PACKARD MODEL HP 7035B ...

Page 9: ...FIGURE 1 4 DIMENSION DRAWING FIGURE 1 5 ACCESSORIES 1 3 ...

Page 12: ...FIGURE 1 7 TYPICAL FREQUENCY RESPONSE INPUT FILTER FIGURE 1 8 TYPICAL DYNAMIC RESPONSE 1 6 ...

Page 14: ...FIGURE 2 1 WING BRACKET INSTALLATION FIGURE 2 2 STACKED CONFIGURATION 2 2 ...

Page 16: ...FIGURE 3 1 FRONT PANEL CONTROLS 7035B AND 7035B 001 MODELS 3 2 ...

Page 20: ...FIGURE 4 1 BLOCK DIAGRAM FIGURE 4 2 DETAILED BLOCK DIAGRAM 4 2 ...

Page 48: ...TM 11 6625 2850 14 P FIGURE 6 1 EXPLODED VIEW CABINET 6 9 ...

Page 49: ...TM 11 6625 2850 14 P FIGURE 6 2 EXPLODED VIEW CARRIAGE ARM SHEET 1 OF 2 6 10 ...

Page 58: ...FIGURE 7 1 COMPONENT IDENTIFICATION FRAME 7 8 ...

Page 59: ...TM 11 6625 2850 14 P Figure 7 2 Component Identification Circuit Board 7 9 ...

Page 60: ...TM 11 6625 2850 14 P Figure 7 3 Schematic Model 7035B D 07035 92550 7 10 ...

Page 62: ...TM 11 6625 2850 14 P FIGURE 8 1 COMPONENT IDENTIFICATION CIRCUIT BOARD 8 2 ...

Page 66: ...TM 11 6625 2850 14 P FIGURE 8 5 EXPLODED VIEW CARRIAGE ARM 8 6 ...