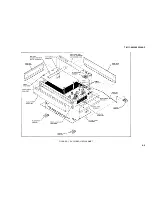

FIGURE 5-22. DRIVE TRAIN ADJUSTMENTS

5-82. X GEAR TRAIN BACKLASH ADJUSTMENT

5-83. Backlash of the gear drive system may be adjusted as

follows:

a.

Remove rear hood, platen, and bottom cover. See

paragraph 5-18.

b.

Using a 1/4 inch nut driver, slightly loosen two clamps

which mount X-axis pulley and pinion on underside of chassis.

See Figure 5-22.

c.

Using thumb and fingers, rotate housing first in one

direction and then other, while moving pen arm from side to

side, until gear rotates freely with minimum backlash. A slight

amount of backlash is desirable for optimum operation.

d.

Tighten mounting clamps and recheck for minimum

backlash. If minimum backlash not attained, repeat above

steps.

e.

Reassemble.

5-84. X-AXIS TRACK BEARING ADJUSTMENT

5-85. Adjustment of the X-axis track bearing is accomplished

as follows:

a.

Remove rear hood, rear side panel, and bottom

cover. See paragraph 5-18.

b.

Move pen arm until it is opposite access slot.

c.

Using Phillips Pozidrive screwdriver, turn bearing

adjusting screw until a slight amount of clearance is detectable

between the five ball bearing rollers and track rod.

d.

Reassemble.

CAUTION

Do not overtighten this adjustment. This

could result in bearing damage or failure.

5-86.

X-AXIS DRIVE TRAIN BEARING REPLACEMENT

5-87. To replace any of the X-axis drive bearings, the X-axis

drive cable must be partially or completely removed,

depending on which bearing is affected. See Figure 5-23.

5-88. PULLEY BEARING REPLACEMENT. To replace either

pulley bearing, proceed as follows:

a.

Remove rear hood and platen. See paragraph 5-18.

b.

Move pen carriage to its extreme position away from

affected pulley.

c.

Apply masking tape to remaining pulley and drive

sheave so as to prevent cable from slipping off when tension is

removed.

d.

Remove bottom cover. See paragraph 5-18.

e.

While holing pulley nut on bottom side of recorder,

remove No. 6-32 screw mounting pulley. Remove pulley and

its mounting stud.

f.

Press out defective bearing. Replace with new

bearing, Part No. 1410-0215.

g.

Reassemble, making sure pulley is reinstalled with flat

side up, as is other pulley.

5-89. DRIVE SHEAVE BEARING REPLACEMENT. To

replace, proceed as follows:

a.

Remove rear hood and platen. See paragraph 5-18.

b.

Remove X-axis drive cable.

c.

Remove retaining ring and slip sheave/gear assembly

upwards and off stud.

d.

Separate gear from sheave by removing 2 No. 2-56

flat head mounting screws with a Phillips screwdriver.

e.

Push bearings (2) out bottom of sheave and replace

with new bearing(s), Part No. 1410-0277.

f.

Restring X-axis. See paragraph 5-44.

g.

Reassemble.

5-90. BELT PULLEY BEARING REPLACEMENT. Replace as

follows:

a.

Remove rear hood, platen, and bottom cover. See

paragraph 5-18.

b.

Loosen two motor clamping screws (Figure 5-22).

Rotate motor until belt is as loose as possible.

5-13

Summary of Contents for HP-7035B

Page 1: ...TECHNICAL MANUAL HEWLETT PACKARD MODEL HP 7035B ...

Page 9: ...FIGURE 1 4 DIMENSION DRAWING FIGURE 1 5 ACCESSORIES 1 3 ...

Page 12: ...FIGURE 1 7 TYPICAL FREQUENCY RESPONSE INPUT FILTER FIGURE 1 8 TYPICAL DYNAMIC RESPONSE 1 6 ...

Page 14: ...FIGURE 2 1 WING BRACKET INSTALLATION FIGURE 2 2 STACKED CONFIGURATION 2 2 ...

Page 16: ...FIGURE 3 1 FRONT PANEL CONTROLS 7035B AND 7035B 001 MODELS 3 2 ...

Page 20: ...FIGURE 4 1 BLOCK DIAGRAM FIGURE 4 2 DETAILED BLOCK DIAGRAM 4 2 ...

Page 48: ...TM 11 6625 2850 14 P FIGURE 6 1 EXPLODED VIEW CABINET 6 9 ...

Page 49: ...TM 11 6625 2850 14 P FIGURE 6 2 EXPLODED VIEW CARRIAGE ARM SHEET 1 OF 2 6 10 ...

Page 58: ...FIGURE 7 1 COMPONENT IDENTIFICATION FRAME 7 8 ...

Page 59: ...TM 11 6625 2850 14 P Figure 7 2 Component Identification Circuit Board 7 9 ...

Page 60: ...TM 11 6625 2850 14 P Figure 7 3 Schematic Model 7035B D 07035 92550 7 10 ...

Page 62: ...TM 11 6625 2850 14 P FIGURE 8 1 COMPONENT IDENTIFICATION CIRCUIT BOARD 8 2 ...

Page 66: ...TM 11 6625 2850 14 P FIGURE 8 5 EXPLODED VIEW CARRIAGE ARM 8 6 ...