MAINTENANCE

7-119

L. Miscellaneous

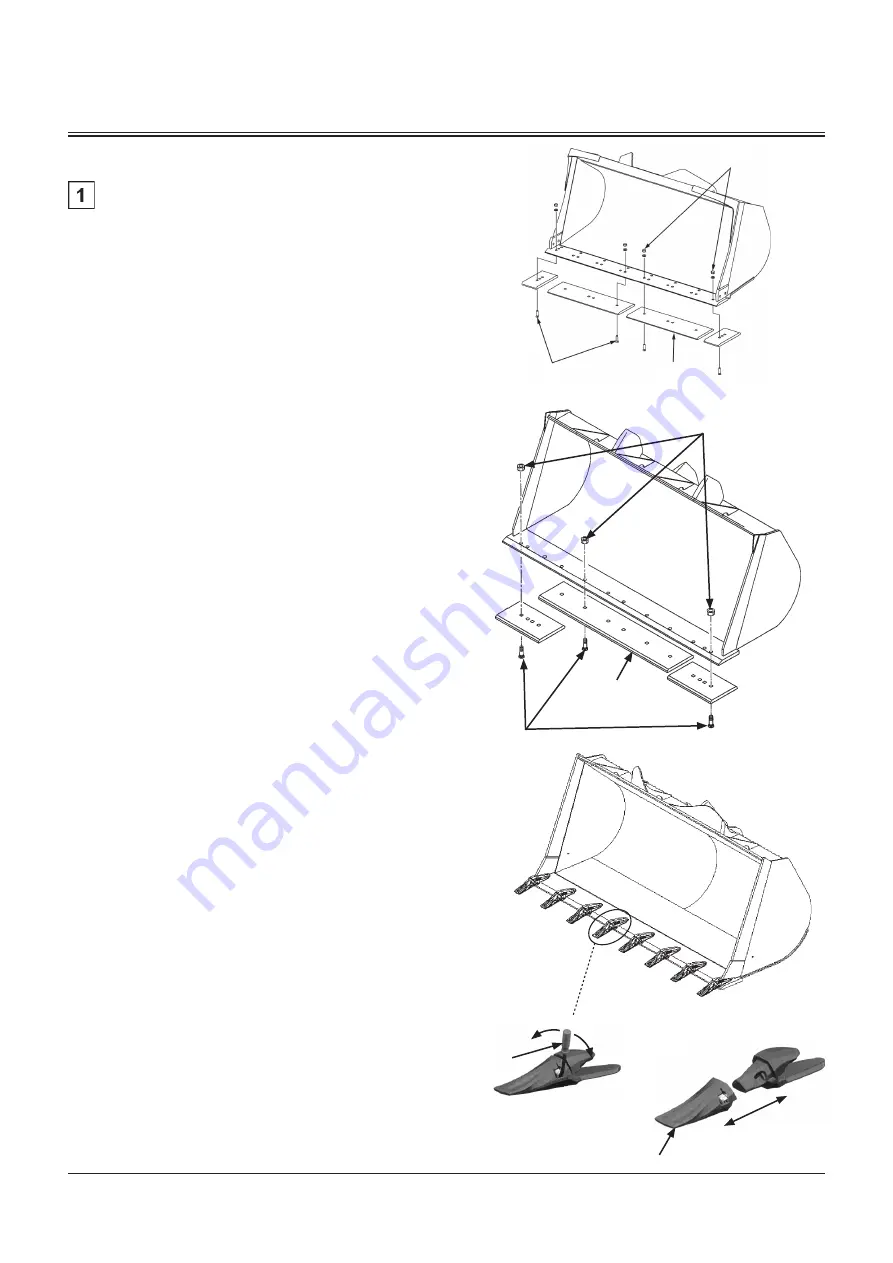

Check Bucket Teeth and Cutting Edge

--- every 10 hours (daily)

Check bucket teeth for wear and looseness.

Replace

d

WARNING: Guard against injury from flying pieces of

metal.

Wear goggles or safety glasses, hard hat and face

shield.

Cutting Edge

1. Lift the bucket so its bottom is level. Lift the bucket to

an appropriate height and wedge a block under it so the

bucket will not come down. Stop the engine.

2. Loosen bolts (1) and nuts (2). Remove cutting edge (4).

3. Install new cutting edge (4). If the reverse side of a

cutting edge is not worn much, use it again with the face

reversed. If both sides are worn out, replace it with a new

one.

4. Tighten nuts (2).

Tightening torque

Cutting edge

: 1068 N·m (107 kgf·m)

5. Retighten mounting nuts (2) after a few hours of

operation.

Bucket Teeth

1. Lift the bucket so its bottom is level. Lift the bucket to

an appropriate height and wedge a block under it so the

bucket will not come down. Stop the engine.

2. Insert a prybar into the locking part of the tooth, unlock

it and remove the point.

3. Remove the point of the tooth.

4. Mount a new point and lock it with the prybar.

5. After operating the machine for several hours, check and

make sure there are no problems with the mounting of

the point.

M4GB-07-116

Point

Lock

Unlock

prybar

MNEK-07-041

MNEK-07-046

MNEK-07-045

90Z7-7-95-2

4

1

2

2

1

4

Summary of Contents for ZW 310-6

Page 4: ......

Page 10: ...CONTENTS MEMO ...

Page 14: ...INTENDED USE 2 MEMO ...

Page 57: ...SAFETY SIGNS S 43 ZW310 6 SS 3777 2 ...

Page 59: ...SAFETY SIGNS S 45 ZW330 6 92Z7B S 40EU ...

Page 246: ...BREAK IN 2 2 MEMO ...

Page 280: ...DRIVING MACHINE 4 20 MEMO ...

Page 460: ...MAINTENANCE 7 146 MEMO ...

Page 464: ...MAINTENANCE UNDER SPECIAL ENVIRONMENTAL CONDITIONS 9 4 MEMO ...

Page 468: ...STORAGE 10 4 MEMO ...

Page 474: ...TROUBLESHOOTING 11 6 MEMO ...

Page 498: ...INDEX 14 6 MEMO ...

Page 502: ...CONFORMITY MEMO ...

Page 506: ......