44

Chapter 3 Installation

|

Hillstone

Hillstone SG-6000 X-Series Hardware Reference Guide

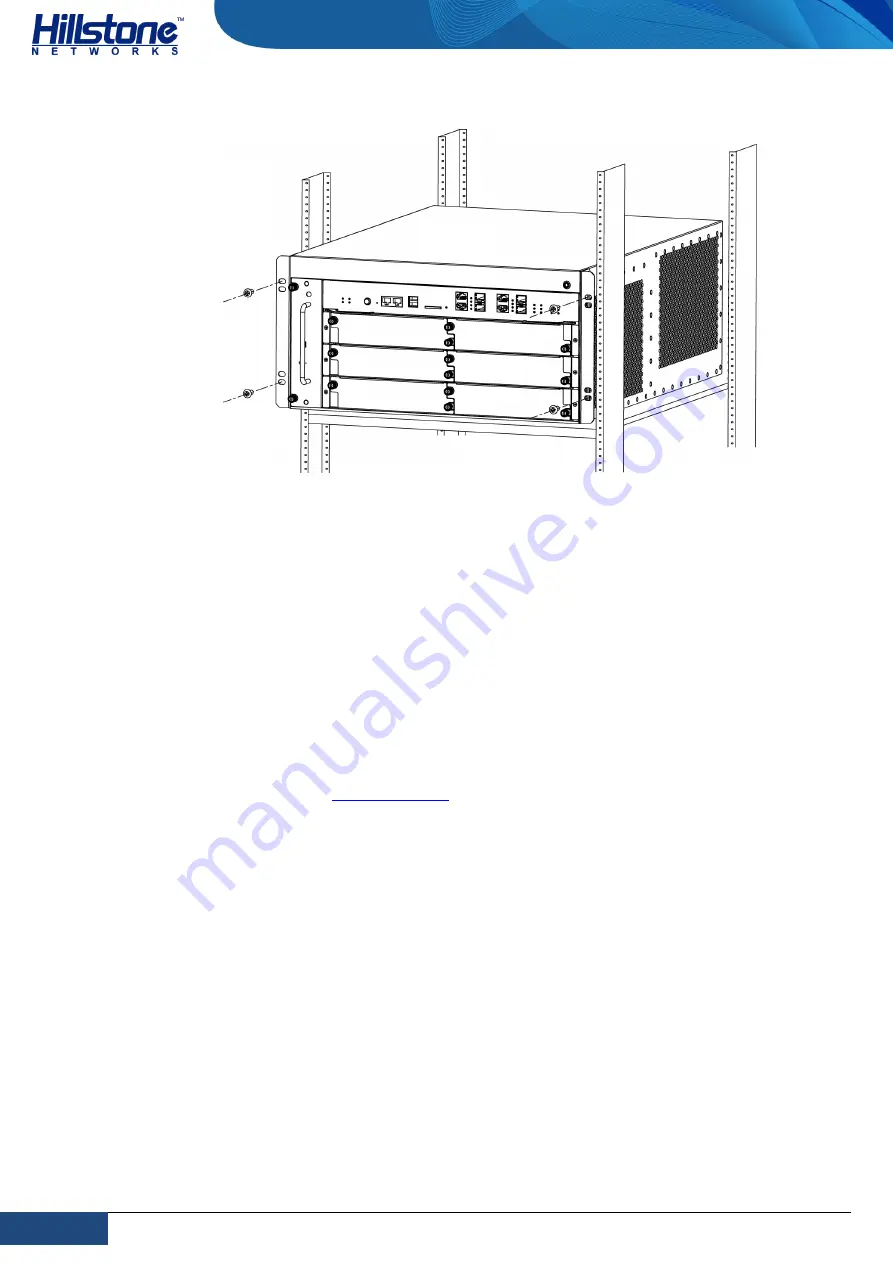

Figure 3-7: Installing the Device in a Rack

7.

Verify the installation. Make sure every two screw pairs are in the same

horizontal line and the device is stably placed on the plate.

Installing the Device without a Lift

If you do not use a lift to install the device, you should remove all parts that can be

removed from the chassis and re-install them when the chassis is properly positioned.

When all hardware components are removed, the chassis weighs 30.8kg, and it

requires at least two people to install the appliance.

To install the device without a lift, take the following steps:

1.

Wear an ESD strap and connect the other end of the strap to the ESD point on

the chassis. See

2.

Make sure the device is not powered and it will not be powered during the

removing process.

3.

Dismantle all the removable components, including power modules, all

expansion modules (SSM, SCM, QSM and IOM), blank plates and fan trays.

4.

Label all the removed parts so that you can reinstall them in the correct location.

5.

Move the chassis in front of the rack.

6.

With one person standing on each side, lift the chassis onto the tray of the rack

or cabinet.

7.

Use the screws to attach the left and right brackets to the rack.

8.

Verify the alignment of the screws. Make sure every two screw pairs are in the

same horizontal line.