4

APP-001f

SEPT 2016

SUCTION LINE

A 1” (25 mm) suction line should be connected to a suction

accumulator, see Figure 3. The purger evaporator shell

temperature sensor is factory set at 40°F (4°C). To allow for

temperature transfer losses between the purger evaporator

and the temperature sensor, the suction temperature

should be approximately 20°F (–7°C) or below. This then

switches the AUTO-PURGER Plus from 3333 EVAP TEMP

>40F (4C) to COLLECTING AIR/WATER mode. For higher

suction temperatures, consult the factory.

RELIEF VALVE VENT LINE

A relief valve vent line should be connected to appropriately

vent any potential relief valve discharge in accordance with

applicable codes, for example ANSI/ASHRAE Standard 15,

Safety Standard for Refrigeration Systems, see Figure 6.

WATER BUBBLER FILL LINE

An automatic water bubbler flush system is provided

with the purger. A water line must be connected to the

water bubbler fill line solenoid valve (D), see Figure 6. The

connection is ½” FPT. The water supply pressure should

be 30–80 psig (2.1–5.5 barg).

LOW-PRESSURE PUMPED-LIQUID LINE

A ½” (13 mm) low-pressure pumped-liquid source is

required for the AUTO-PURGER Plus. This connection

should be from the pump discharge of the lowest pressure

recirculator, see Figure 3. This connection should be at a

location where oil will not be directed into the purger. The

low-pressure pumped-liquid line feeds makeup liquid as

required during purging. The line contains liquid ammonia

that typically is also contaminated with water which is to

be removed by the AUTO-PURGER Plus. The liquid line

solenoid valve (B) on the AUTO-PURGER Plus closes when

the AUTO-PURGER Plus is off, see Figure 6.

If the system contains more than one vessel that does

not feed liquid to any other lower pressure vessel,

then separate pipes may need to be installed, with

corresponding shutoff valves, so that liquid can periodically

be drawn from each vessel which may contain water. The

liquid pressure must be a minimum 15 psi (1.0 bar) higher

than the APPT suction for the liquid to feed properly.

LOW-PRESSURE LIQUID RETURN LINE

A ½” (13 mm) low-pressure liquid return line is required

for the AUTO-PURGER Plus. Ammonia vapor from the

foul gas line is condensed to liquid in the air separator

chamber. This condensed liquid ammonia flows to the

suction accumulator through the low-pressure liquid

return line, see Figure 3.

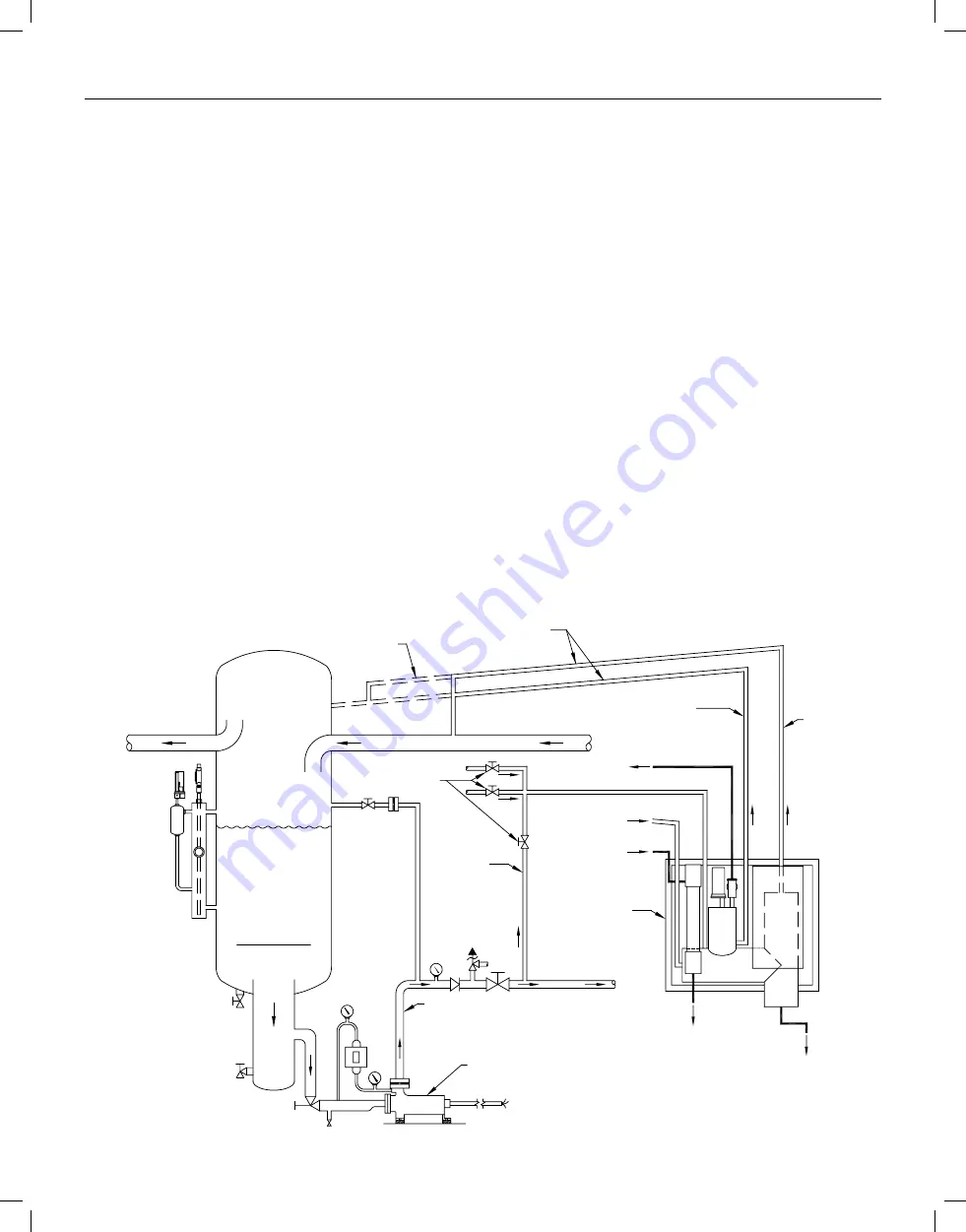

AUTO-PURGER PLUS APPT PIPING DIAGRAM

Figure 3

TO COMPRESSORS

FROM EVAPORATORS

PUMP

DISCHARGE

LINE

TO SYSTEM

FILL LINE

WATER BUBBLER

DRAIN LINE

WATER BUBBLER

FROM PURGE POINTS

FOUL GAS LINE

LINE

WATER PURGE

VENT LINE

RELIEF VALVE

PUMPED

LIQUID LINE

SUCTION

LINE

LOW PRESSURE

LIQUID RETURN LINE

REFRIGERANT PUMP

OPTIONAL

PIPING

PITCH LINES TOWARD

RECIRCULATOR

AUTO-PURGER

PLUS

SHUT-OFF VALVES

TO SWITCH FROM

MULTIPLE VESSELS

LOWEST PRESSURE

RECIRCULATOR

This drawing is for illustration purposes only

and should not be used for actual engineering

or installation. Not to scale.

Note: For APPT piping diagram to controlled pressure receiver (CPR) system, request Hansen sales drawing #2003-04.

SECTION 2 INSTALLATION