Needle Bar Height

(2 of 2)

5.

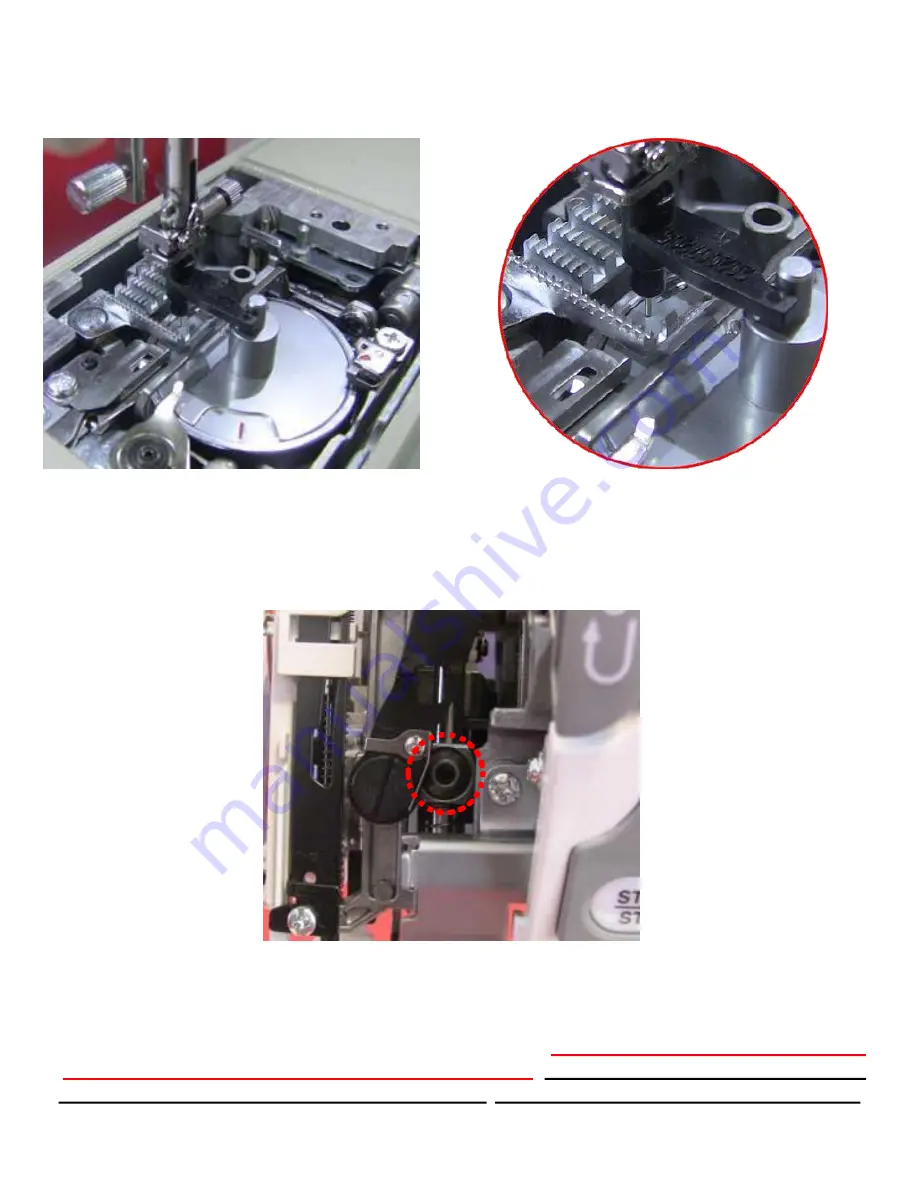

As you continue to turn the hand wheel toward you, the needle bar height gauge should

lightly skim the top of the gauge. There should not be a gap between the gauges and the

needle bar height gauge should not hit the radial gauge enough to shift the needle bar

sideways.

6.

If an adjustment needs to be made, provide resistance against the adjustment by holding

onto the needle bar with one hand, locate and loosen the hex screw with a 2mm hex tool on

the block that holds the needle bar in place. This is the larger of the two blocks on the

needle bar. Raise or lower the needle bar accordingly.

Do not turn the needle bar left or

right

, because this will affect the needle threader.

Note when the needle is installed

correctly the long groove should be straight at the front where the sewer is sitting

.

Retighten the needle bar driver screw. Recheck

the adjustment.

3

9