D

A5

Thread

cutter

symbol

CORRECT CONDITION

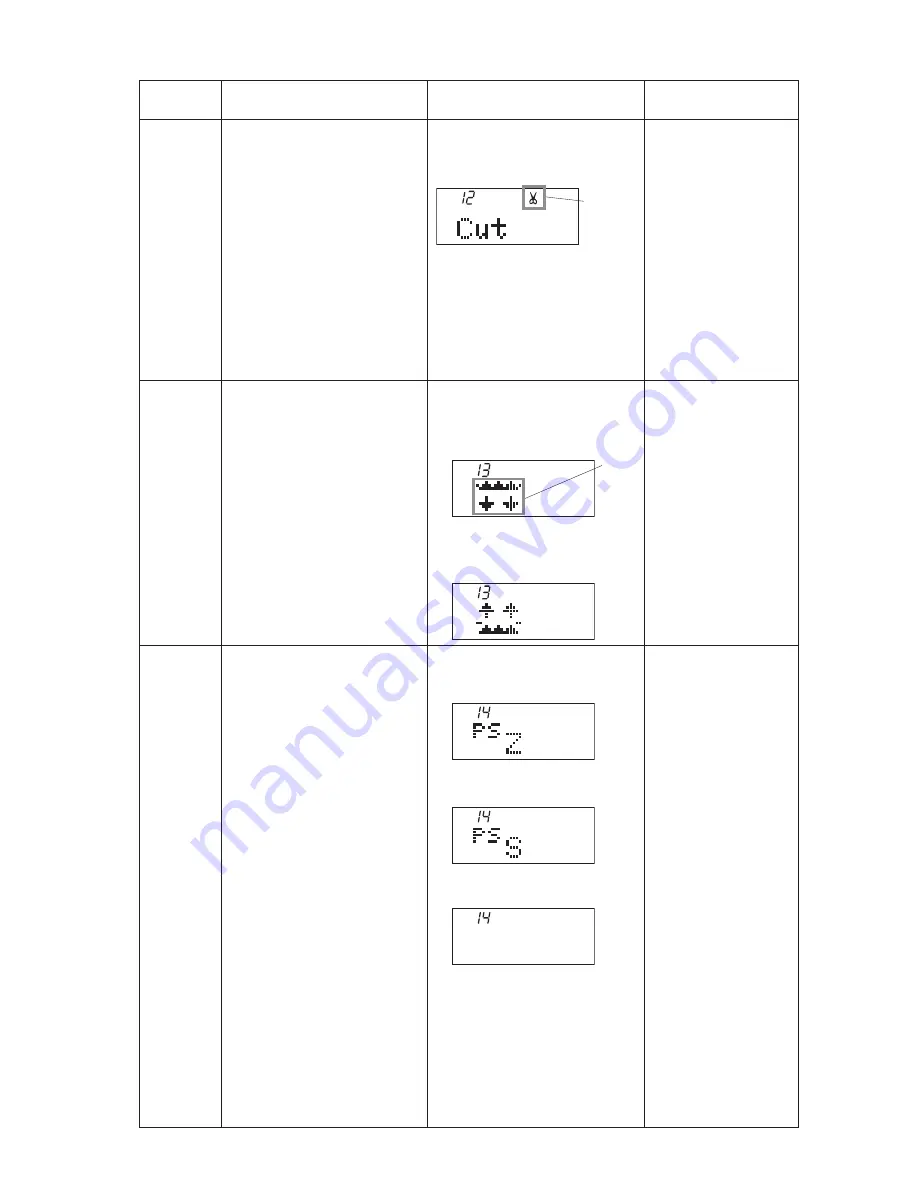

LCD displays “12” and “Cut”.

The thread cutter symbol will blink, and

thread cutter motor will be initialized.

STEP AND

ITEMS TO

CHECk

12)

THREAD

CUTTER

MOTOR,

THREAD

CUTTER

SOLENOID

PROCEDURE

Turn the handwheel toward you to

raise the needle bar at its highest

position. Press the needle up/down

button.

If the result is correct condition,

press the start/stop button to

proceed the next step.

If the result is defective condition,

press the reverse stitch button to

proceed the next step.

DEFECTIVE CONDITION

Thread cutter motor does

not work.

LCD displays “E4”.

–REMEDY–

Replace the thread cutter

motor.

Adjust the sensor plate

position.

Replace the printed

circuit board A.

13)

FEED DOG

Turn the drop feed lever to the

right.

Turn the drop feed lever to the left.

If the result is correct condition,

press the start/stop button to

proceed the next step.

If the result is defective condition,

press the reverse stitch button to

proceed the next step.

LCD displays “13” and feed dog symbol.

When the drop feed lever is turned to

the right, LCD displays as Fig. 1.

When the drop feed lever is turned to

the left, LCD displays as Fig. 2.

Fig. 1

Feed

dog

symbol

Fig. 2

14)

NEEDLE

PLATE

LCD displays “14”.

When the needle plate is attached to

the machine, LCD displays “PSZ”.

When the needle plate for straight

stitch is attached to the machine, LCD

displays “PSS”.

When nothing is attached to the

machine, LCD displays “14” only.

Attach the needle plate.

Attach the needle plate for straight

stitch.

If the result is correct condition,

press the start/stop button to pro-

ceed the next step.

If the result is defective condition,

press the reverse stitch button to

proceed the next step.

Feed Dog

symbol does

not change.

Buzzer

does not sound.

–REMEDY–

Replace the drop feed dog

lever unit.

Replace the printed circuit

board A.

LCD does not change.

LCD displays “PSErr”.

Buzzer does not sound.

–REMEDY–

Replace the needle plate

sensor.

Replace the printed

circuit board A.