SPANNTOP [nova] – Assembly

Fig. 30

2. Lift the clamping unit [1] off of the spindle flange.

3. Wipe off the mating surfaces on the spindle flange

and clamping unit with a soft, lint-free cloth and re-

move all oil and grease residues.

4. Hone the mating surfaces on the spindle flange

with an oil stone.

6.2.2 Preparing the SPANNTOP nova modular clamping device

5. x

Special tools required:

Allen wrench

Oil stone

Crane and eye bolts from weight 15 kg

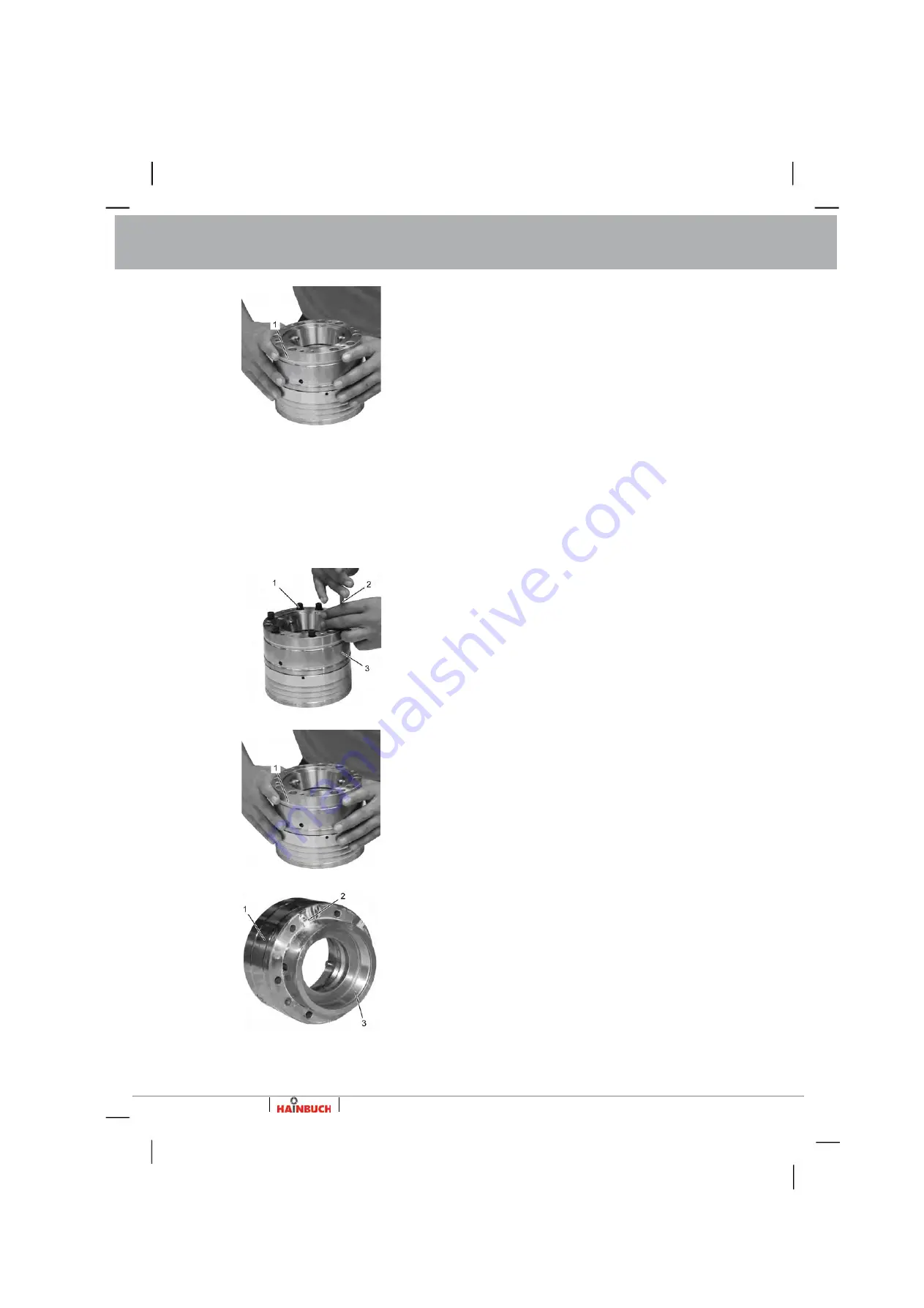

Fig. 31

1. Loosen all cylindrical screws [1] in the clamping

device element reception [3] with an allen wrench

[2] and remove them completely.

Fig. 32

2. Lift the clamping element reception [1] off of the

spindle flange.

Fig. 33

3. Take the coupling [3] out of the spindle flange [1].

In this process ensure that the torsional safety pin

[2] is kept safe and is not damaged.

4. Clean the mating surfaces on the spindle flange,

drawtube adapter, coupling, and clamping unit with

a soft, lint-free cloth and remove all oil and grease

residues.

5. Hone the mating surfaces on the spindle flange

with an oil stone.

66