GE Grid Solutions

D25

User's Manual

GE Information

994-0081-3.00-21

105

Chapter 5: Operating the D25

LED Indicators

Front Panel

Indicators

The front panel has three sets of LED indicators, providing a visual indication

of the operational status of the unit:

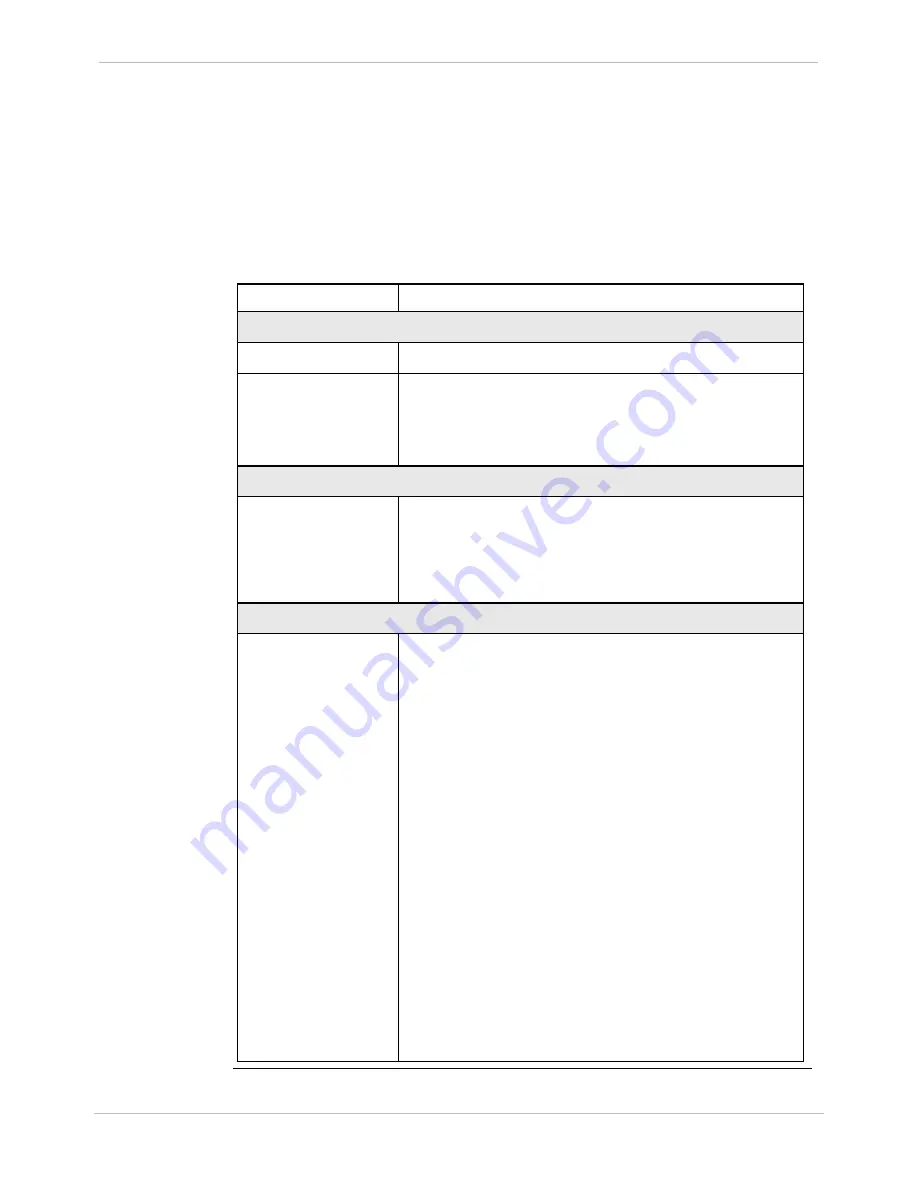

LED

Color and Function

OPERATION

POWER

Green: on when power supply is operating normally.

RUN

Green: on when the D25 microprocessor system is

running. With a Type III WESDAC board the

RUN

LED

flashes at about 2 Hz, depending on processor

load.

COMMUNICATIONS

IED1 (COM 3)

IED2 (COM 4)

XCOM 1 (COM 5)

XCOM 2 (COM 6)

Red: on to indicate whether and when each port is

transmitting (TX) and/or receiving (RX):

Note

: XCOM indicators light

only

if card is

installed.

CONTROLS

LOCAL

REMOTE

The D25 Plant I/O Subsystem monitors the state of

the

CONTROLS

switch

only if

a control board is

installed.

If the

CONTROLS

switch is in the

REMOTE

position at startup:

•

green

LOCAL

LED lights immediately when the D25

is turned on.

•

green LED remains on until the D25’s internal POST

diagnostics are complete.

•

if the diagnostics do not pass, the indicator remains

green.

After the D25 has started up normally, the indicator

should follow the state of the

CONTROLS

switch:

•

if the switch is moved to the

REMOTE

position, the

red

REMOTE

LED lights after a momentary delay,

and the

LOCAL

LED turns off.

Local/Remote LEDs flashing indicate one or more active

sealed-in outputs (only if a D25 High Current KE Control

Output Module is present in the D25)

Summary of Contents for D25

Page 170: ......