Setting the default trend type

1.

From Super User mode, select

System Config.

and then

Trends Setup

.

2.

Select

Default Trend

and then select the trend type from the

drop-down list.

Graphical

shows the graphical trends.

Measured

shows the numeric trends.

Settings

shows the trends for the settings.

3.

See the "

Setting graphical trends pages

setting up trends or select

Back

to return to the

System Config.

menu.

Setting graphical trends pages

Use the Graphical Page section to configure the graphical trends

pages for the

Trends

menu.

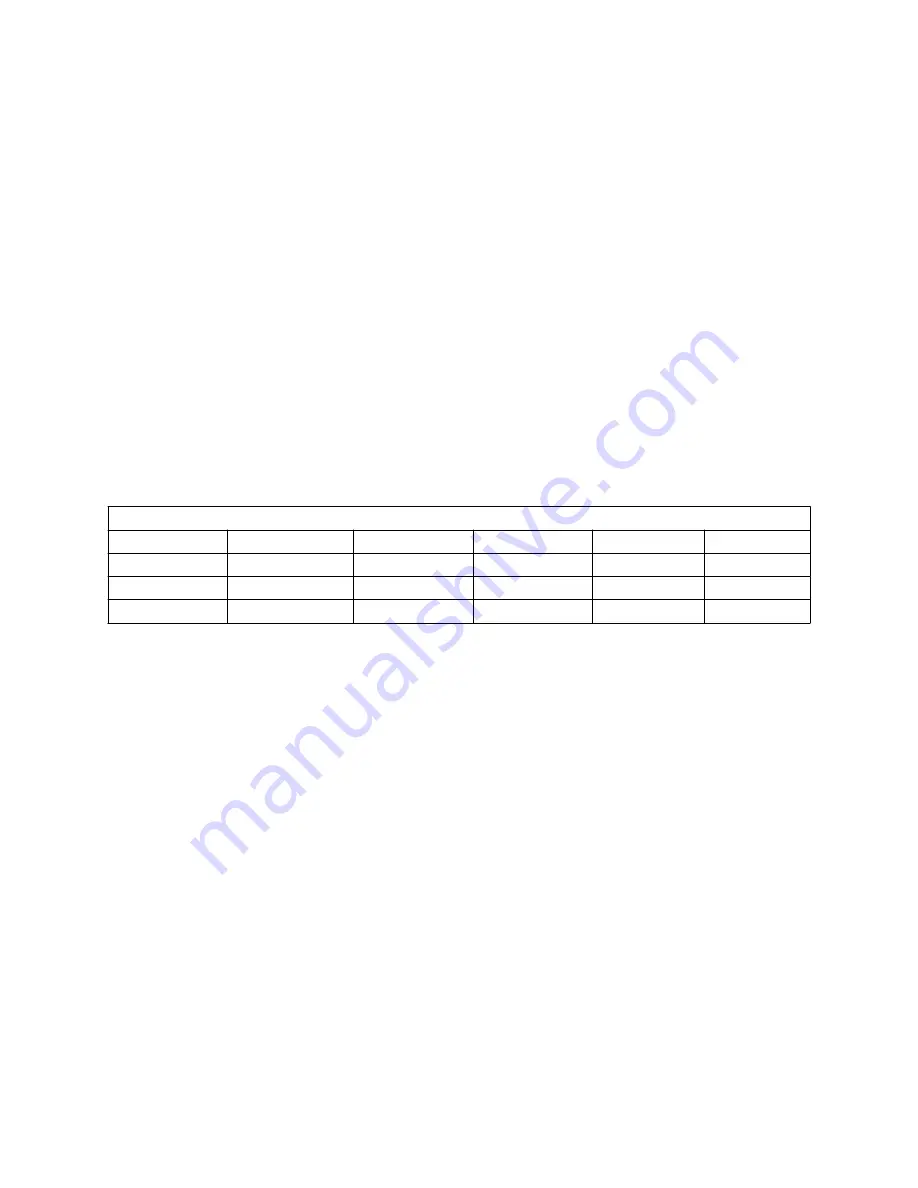

The table shows the factory default settings for each trend page.

.

Default settings for Trends on each Page

Page 1

Page 2

Page 3

Page 4

Page 5

Top

Pres

O2

AA2

Bal

RR + CO2

Middle

TVexp

N2O

N2O

MAC

Compl

Bottom

CO2

AA1

MAC

MVexp

Off

1.

From the Super User mode, select

System Config.

and then

Trends Setup

.

2.

Use the drop-down lists to set

Top Trend

,

Middle Trend

, and

Bottom Trend

to show the desired parameters.

3.

Select

Next Page

to set up graphical trend defaults for another

page or

Back

to return to the

System Config.

menu.

Page setup

Use the

Pages Setup

menu to set the default screen views for

waveform fields, digit fields, and split screen areas. Four default

screen views can be configured.

Carestation

™

620/650/650c (A1)

12-8

2076152-001

Summary of Contents for Carestation 620

Page 1: ...Carestation 620 650 650c A1 User s Reference Manual Software Revision 01...

Page 12: ...Carestation 620 650 650c A1 x 2076152 001...

Page 58: ...2 24 2076152 001...

Page 98: ...3 40 2076152 001...

Page 102: ...4 4 2076152 001...

Page 128: ...6 12 2076152 001...

Page 150: ...7 22 2076152 001...

Page 182: ...8 32 2076152 001...

Page 196: ...9 14 2076152 001...

Page 246: ...11 44 2076152 001...

Page 268: ...Carestation 620 650 650c A1 User s Reference Manual English 2076152 001 2021 05 Rev S...