13-17-621 Page 62

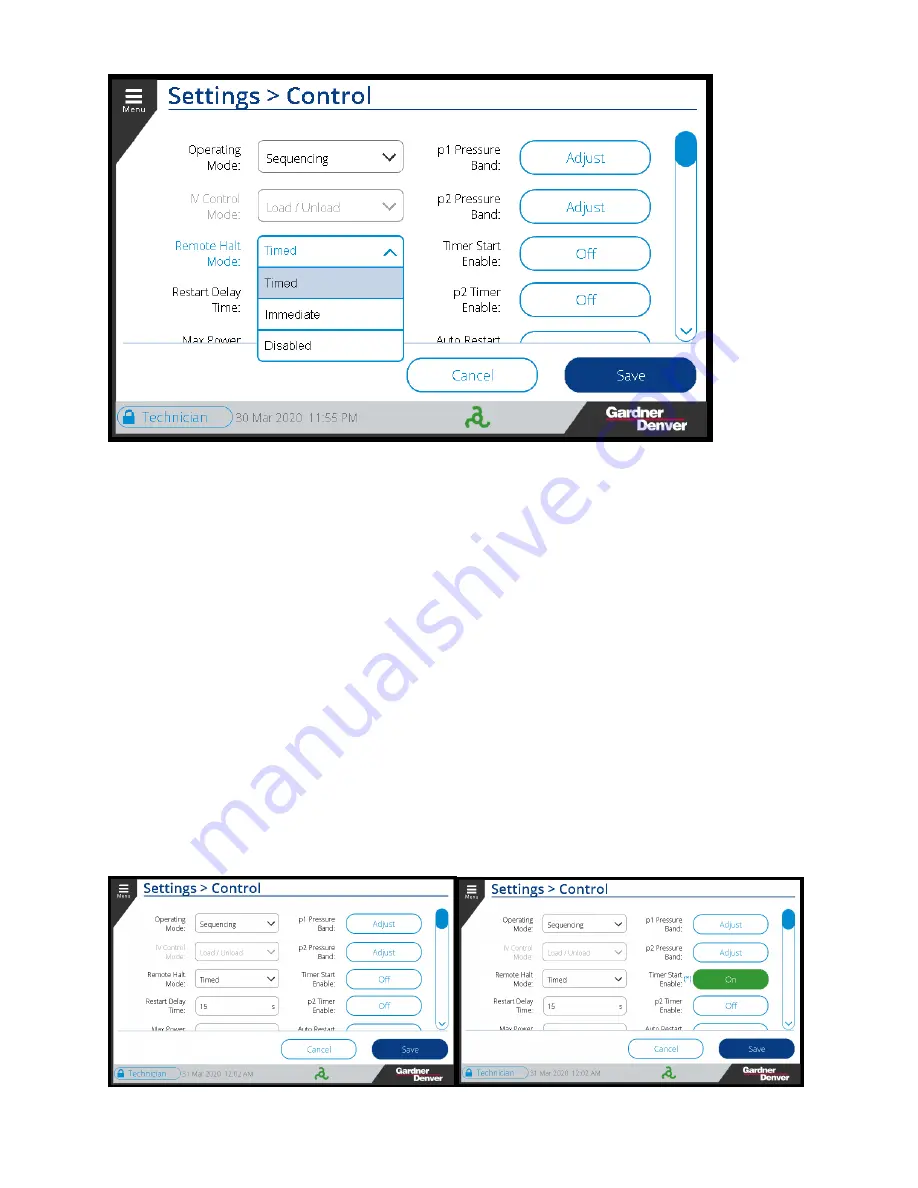

Figure 79: Remote Halt Mode

Timed

mode means the compressor will stop after the unload, blowdown, and automatic stop timers have

expired upon receiving a remote halt signal. The compressor will act as if the pressure exceeded the unload

set point. If the remote halt signal is removed at any point the compressor will re-load, as long as the

pressure is not above the unload pressure set point.

Immediate

mode means the compressor will unload, blowdown, and stop immediately upon receiving a

remote halt signal. This stopping process is essentially the same as if the stop button has been pressed on

the controller.

Disabled

mode is used when there are no remote halt signals programmed to a digital input or when this

function needs to be switched off for any reason. Control will continue locally at the machine controller in

this mode.

4.2.6 Timer Start Enable

Timer Start Enable

allows the user to

enable

or

disable

the starting and stopping of the machine under

timer control. If currently shown as

Off

then pressing it again will toggle it to

O

n and Vice-Versa. Refer

Figure 80 below.

When the

Timer Start Enable

is turned on the compressor will start and stop based on the schedule set

under the timer control settings page. If this is disabled then the compressor will continue to run as

normal regardless of the schedule.

Figure 80: Timer Start Enable