– 135 –

14

Chapter

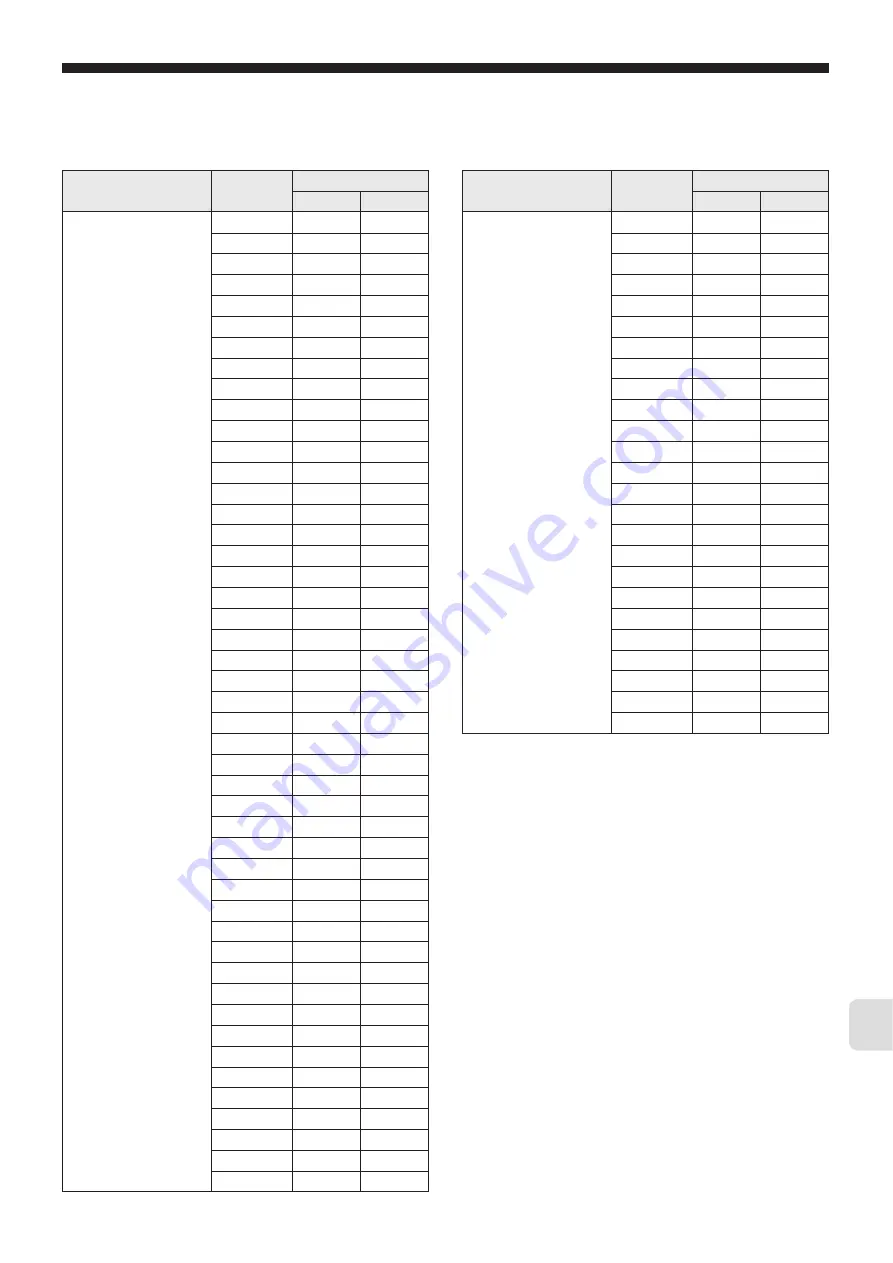

PID palette Ch 3

Sv1

dP05

0

P1

dP05

1

i1

dP05

2

d1

dP05

3

hyS1

dP05

4

CoL1

dP05

5

db1

dP05

6

bAL1

dP05

7

Ar1

dP05

8

rEv1

dP05

9

Sv2

dP05

10

P2

dP05

11

i2

dP05

12

d2

dP05

13

hyS2

dP05

14

CoL2

dP05

15

db2

dP06

0

bAL2

dP06

1

Ar2

dP06

2

rEv2

dP06

3

Sv3

dP06

4

P3

dP06

5

i3

dP06

6

d3

dP06

7

hYS3

dP06

8

CoL3

dP06

9

db3

dP06

10

bAL3

dP06

11

Ar3

dP06

12

rEv3

dP06

13

Sv4

dP06

14

P4

dP06

15

i4

dP07

0

d4

dP07

1

hyS4

dP07

2

CoL4

dP07

3

db4

dP07

4

bAL4

dP07

5

Ar4

dP07

6

rEv4

dP07

7

Sv5

dP07

8

P5

dP07

9

i5

dP07

10

d5

dP07

11

hyS5

dP07

12

CoL5

dP07

13

db5

dP07

14

Display Screen or

Channel

Parameter

dP

No.

Bit position

PID palette Ch 3

bAL5

dP07

15

Ar5

dP08

0

rEv5

dP08

1

Sv6

dP08

2

P6

dP08

3

i6

dP08

4

d6

dP08

5

hYS6

dP08

6

CoL6

dP08

7

db6

dP08

8

bAL6

dP08

9

Ar6

dP08

10

rEv6

dP08

11

Sv7

dP08

12

P7

dP08

13

i7

dP08

14

d7

dP08

15

hyS7

dP09

0

CoL7

dP09

1

db7

dP09

2

bAL7

dP09

3

Ar7

dP09

4

rEv7

dP09

5

SVMX

dP10

0

PL1M

dP10

1

Display Screen or

Channel

Parameter

dP

No.

Bit position

Summary of Contents for PXG4

Page 1: ...c...

Page 10: ...9 1 Chapter Chapter 1 Part Names and Functions Part Names and Functions 10...

Page 21: ...20 MEMO 2 Chapter...

Page 43: ...42 MEMO 4 Chapter...

Page 53: ...52 MEMO 5 Chapter...

Page 71: ...70 MEMO 7 Chapter...

Page 89: ...88 MEMO 8 Chapter...

Page 106: ...105 9 Chapter Behavior when control is lost Limit Cycle PV SV Time tuning MV control lost 100...

Page 119: ...118 MEMO 10 Chapter...

Page 125: ...124 MEMO 11 Chapter...

Page 131: ...130 MEMO 12 Chapter...

Page 141: ...140 MEMO 14 Chapter...

Page 151: ...150 MEMO 15 Chapter...

Page 152: ...151 16 Chapter Chapter 16 Troubleshooting Troubleshooting 152...

Page 157: ...156 MEMO 17 Chapter...