RWB II ROTARY SCREW COMPRESSOR UNITS

PROPER IN STAL LA TION OF ELECTRONIC EQUIPMENT

S70-200 IOM

Page 47

PROPER INSTALLATION OF ELECTRONIC EQUIPMENT

IN AN IN DUS TRI AL ENVIRONMENT

In today’s refrigeration plants, electronic controls have found

their way into almost every aspect of refrigeration control.

Electronic con trols have brought to the industry more pre cise

con trol, im proved energy savings and operator con ve nienc es.

Electronic control devices have rev o lu tion ized the way refrig-

eration plants operate to day.

The earlier relay systems were virtually immune to radio

fre quen cy interference (RFI), electromagnetic interference

(EMI), and ground loop cur rents. Therefore in stal la tion and

wiring were of little con se quence and the wiring job con-

sist ed of hook ing up the point-to-point wiring and sizing the

wire properly. In an electronic system, im prop er in stal la tion

will cause problems that out weigh the benefi ts of electronic

con trol. Electronic equip ment is susceptible to RFI, EMI, and

ground loop currents which can cause equipment shut downs,

processor memory and program loss, er rat ic be hav ior, and

false readings. Manufacturers of in dus tri al elec tron ic equip-

ment take into con sid er ation the effects of RFI, EMI, and

ground loop currents and incorporate pro tec tion of the

elec tron ics in their designs. These man u fac tur ers re quire

that certain installation precautions be tak en to pro tect the

elec tron ics from these ef fects. All electronic equip ment must

be viewed as sen si tive instrumentation and there fore re quires

care ful attention to installation procedures. These pro ce dures

are well known to instrument engineers, but are usu al ly not

followed by general elec tri cians.

There are a few basics, that if followed, will result in a

trou ble-free installation. The Na tion al Electric Code (NEC)

is a guide line for safe wiring practices, but it does not deal

with pro ce dures used for electronic control in stal la tion. Use

the fol low ing procedures for elec tron ic equip ment in stal -

la tion. These pro ce dures do not over ride any rules by the

NEC, but are to be used in con junc tion with the NEC code.

WIRE SIZING

Size supply wires one size larger than re quired for

am per age draw to reduce in stan ta neous volt age dips

caused by large loads such as heat ers and contactors

and so le noids. These sud den dips in volt age can cause the

pro ces sor, whether it be a mi cro pro ces sor, a com put er, or a

PLC to malfunction mo men tari ly or cause a com plete reset

of the control system. If the wire is loaded to its max i mum

ca pac i ty, the volt age dips are much larger, and the potential

of a mal func tion is very high. If the wire is sized one size

larg er than required, the voltage dips are smaller than in a

fully loaded supply wire, and the po ten tial for mal func tion

is much lower. The NEC code book calls for spe cifi c wire

sizes to be used based on cur rent draw. An ex am ple of this

would be to use #14 gauge wire for circuits up to 15 amp or

#12 gauge wire for circuits of up to 20 amp. There fore, when

con nect ing the power feed circuit to an elec tron ic in dus tri al

con trol, use #12 gauge wire for a maximum cur rent draw

of 15 amp and #10 wire for a max i mum cur rent draw of 20

amp. Use this rule of thumb to minimize volt age dips at the

elec tron ic control.

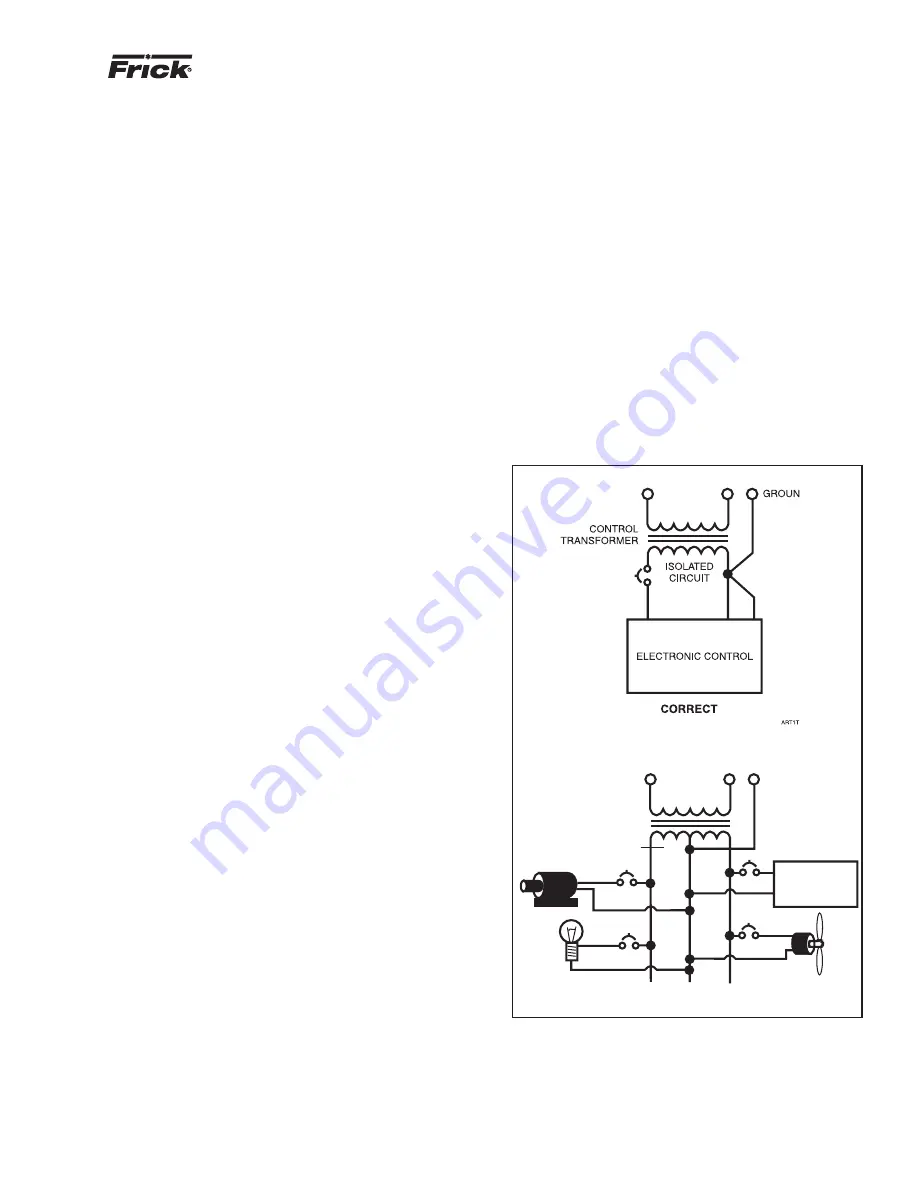

VOLTAGE SOURCE

Selecting the voltage source is extremely im por tant for

prop er operation of elec tron ic equip ment in an in dus tri al en-

vi ron ment. Standard pro ce dure for electronic in stru men ta tion

is to pro vide a “clean” separate source volt age in order to

pre vent EMI, from other equipment in the plant, from in ter -

fer ing with the operation of the electronic equipment. Con-

nect ing electronic equip ment to a breaker panel (also known

as light ing panels and fuse panels) sub jects the electronic

equip ment to noise gen er at ed by other devices con nect ed

to the breaker panel. This noise is known as elec tro mag net ic

in ter fer ence (EMI). EMI fl ows on the wires that are common

to a circuit. EMI can not travel eas i ly through trans form ers

and there fore can be isolated from selected cir cuits. Use

a con trol transformer to isolate the elec tron ic con trol

pan el from other equip ment in the plant that gen er ate

EMI. (Figure 44)

CONTROL

TRANSFORMER

NONISOLATED

CIRCUIT

GROUND

ELECTRONIC

CONTROL

INCORRECT

ART1B

Figure 44