Operation Maintenance Manual

2018-05

PN 9GV73109 - Revision: 02

Safety Spinning Wrench

47

C

O

M

M

IS

SION

IN

G

/

O

PE

R

A

TION

4.3

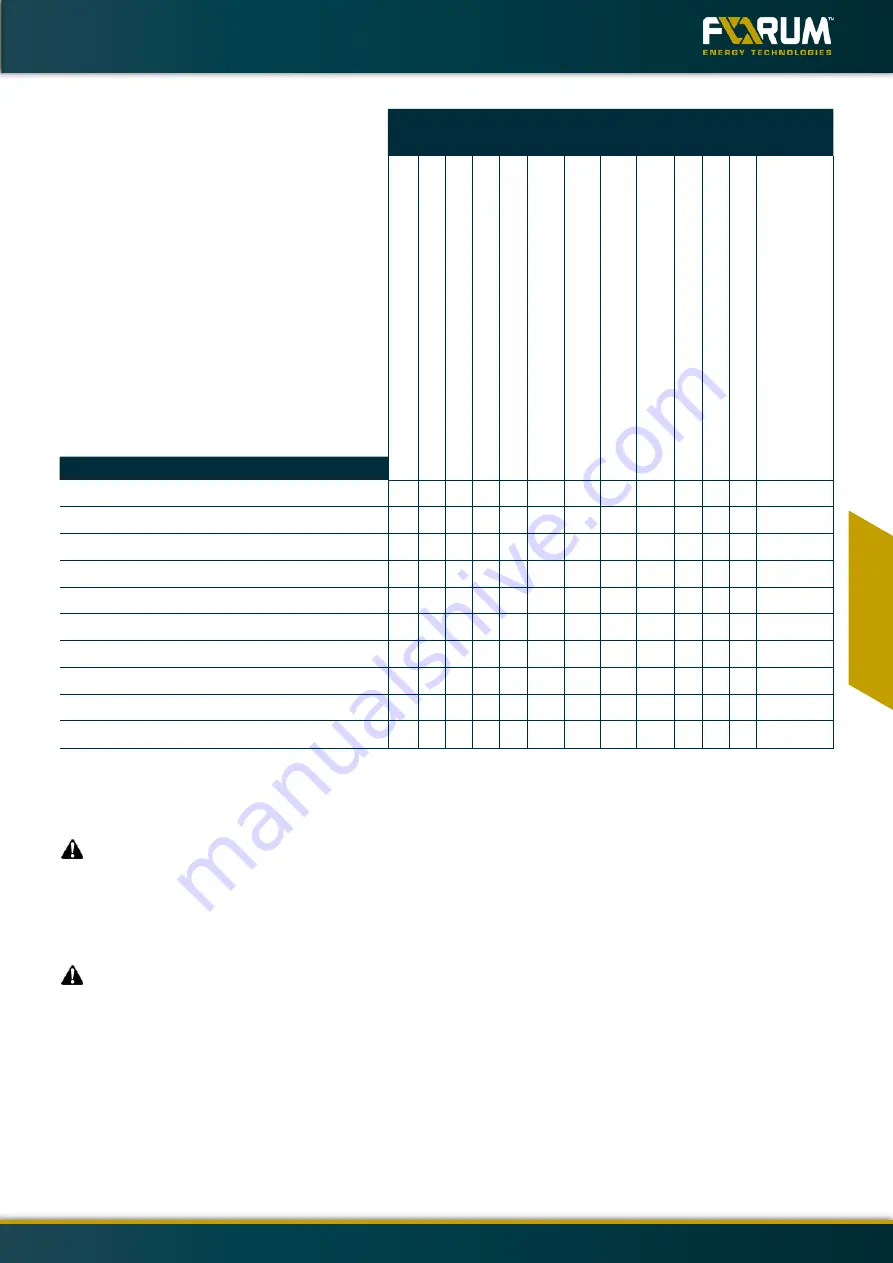

Troubleshooting

Useful steps for troubleshooting

Further

help

Is t

he c

or

re

ct w

or

ki

ng p

re

ssu

re s

et

?

A

re t

he

re l

oo

se

, u

nt

ig

hte

ne

d, c

av

ed o

r d

am

ag

ed h

os

es

?

A

re t

he

re d

am

ag

ed

, l

os

e o

r u

nt

ig

hte

ne

d v

al

ve

s o

r fi

tt

in

gs

?

Is t

he

re d

ir

t o

r o

th

er o

bj

ec

ts i

n t

he w

or

ki

ng a

re

a?

Is t

he w

or

ki

ng r

an

ge a

dj

us

te

d c

or

re

ct

ly

?

A

re t

he

re n

oi

se

s w

hi

ch i

nd

ic

ate d

am

ag

es t

o t

he b

ea

rin

gs

,

ge

ar

in

gs

, t

he a

ir m

ot

or

s o

r o

th

er c

om

po

ne

nt

s?

Is t

he S

SW

-4

0 i

ns

ta

lle

d a

s r

ec

om

m

en

d b

y

Fo

ru

m B + V O

il T

oo

ls?

"

A

re t

he

re l

oo

se

, u

nt

ig

hte

ne

d o

r d

am

ag

ed

com

pone

nt

s e

xc

ep

t p

ne

um

at

ic

c

om

pone

nt

s?

Lu

bric

at

io

n p

oi

nt

s a

re

lu

bric

at

ed

as r

ec

om

m

en

d b

y F

or

um B + V O

il T

oo

ls?

Is

t

he

re

e

nou

gh

e

ng

in

e o

il?

is t

he s

nu

b l

in

e s

en

so

r i

ns

ta

lle

d o

n t

he c

or

re

ct s

id

e?

A

re t

he

re b

lo

ck

ed g

re

as

e n

ip

pl

es

?

C

on

ta

ct T

ec

hn

ic

al Su

pp

or

t i

n c

as

e o

f a

n e

m

er

ge

nc

y, f

or

ad

va

nce

d h

el

p a

nd t

ip

s a

nd e

sp

ec

ia

lly i

f t

ro

ub

le

sh

oo

tin

g i

s

w

ith

out

s

uc

ce

s!

Common Symptoms

The SSW-40 does not clamp.

' ' ' '

'

'

|

The SSW-40 does not unclamp

' ' ' '

'

'

|

Rollers do not rotate.

' ' ' '

'

'

'

' '

|

Rollers do not rotate simultaneously.

|

The rollers run out of centre.

'

'

|

The SSW-40 spins slowly.

' ' '

'

'

'

' '

|

The rollers overrun.

' '

'

|

The SSW-40 is not able to clamp the pipe completely.

' ' ' ' '

'

'

'

'

|

Incorrect lifting and lowering operation.

' ' ' '

'

'

'

|

Device is grease dry unless lubrication has been performed.

'

|

'

FORUM Handling Tools recommends to

follow this step in case of unsolvable problems!

|

FORUM Handling Tools

recommends

to follow this shown step.

NOTE

Due to the complexity of the SSW-40, this table does not show all possible fault symptoms. As

different symptoms may occur in combination, it is necessary to go through troubleshooting in a useful order,

FORUM Handling Tools recommends that the operator contact FORUM Technical Support prior to lengthy

troubleshooting activity. Contact technical support, even if there are only single components or assemblies,

which have to be replaced!

WARNING

Always follow the recommend safety notes while troubleshooting.

- Do not perform any troubleshooting while the equipment is in operation.

- Do not forget to switch off and relieve pressure before installing new components or manometer.

- Do not make any form of reparation, expansion or changes, which are not recommend and supported by

FORUM Handling Tools.