6

Control via FHPP

Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English

53

6.2.2

Methods of homing

The homing method to be selected depends on the parameterised axis, application and condition of the

system.

The homing methods are oriented on CANopen CiA 402.

Accuracy of the homing point

To increase the absolute positioning accuracy, the zero pulse of the incremental encoder

can be used for evaluation.

Software end positions

The software end positions are deactivated with the start of homing and activated again

after homing is completed.

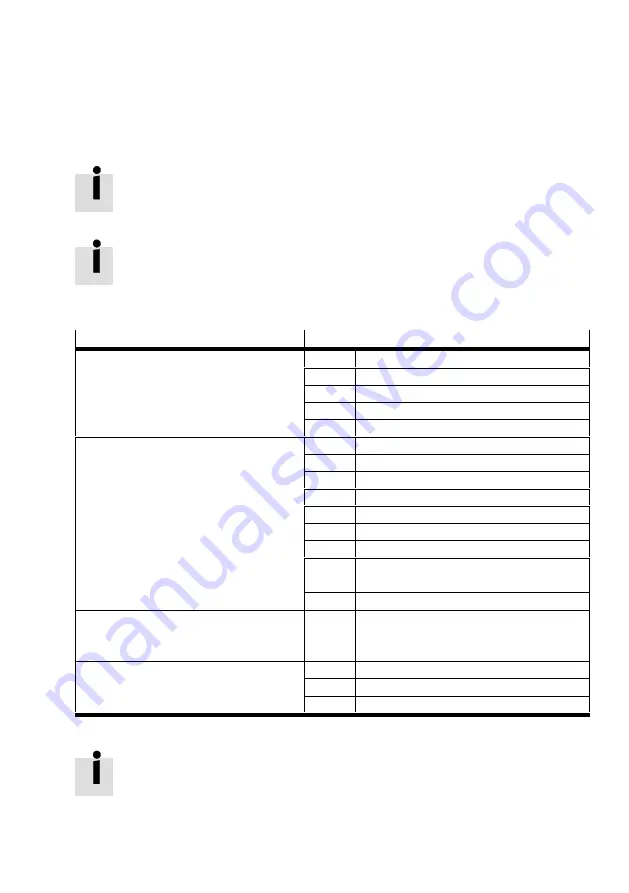

The following homing methods are possible, depending on the motor configuration.

Motor/operation/reference switch

Possible homing methods

Motor with encoder in controlled operation

(closed loop) without reference switch

-35

Current position

33

Current po index – negative direction

34

Current po index – positive direction

-17

Stop – negative direction

-18

Stop – positive direction

Motor with encoder in controlled operation

(closed loop) with reference switch

-35

Current position

33

Current po index – negative direction

34

Current po index – positive direction

-17

Stop – negative direction

-18

Stop – positive direction

27

Reference switch – positive direction

23

Reference switch – negative direction

11

Reference index – negative direc

tion

7

Reference index – positive direction

Motor without encoder or in controlled op

eration (open loop) without reference

switch

-35

Current position

Motor without encoder or in controlled op

eration (open loop) with reference switch

-35

Current position

27

Reference switch – negative direction

23

Reference switch – positive direction

Tab. 6.2

Possible homing methods

Information on the sequence of homing methods

è

equipment and functional descrip

tion of the motor controller, GDCP-CMMO-ST-LK-SY-....

Summary of Contents for CMMO-ST-C5-1-LKP

Page 182: ......