Switching

Between

Continuous and Single Sheets

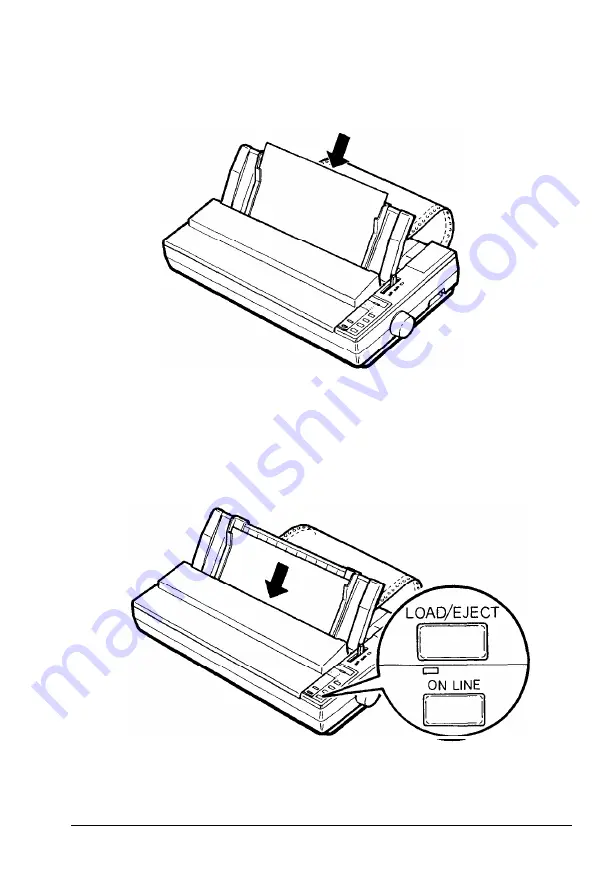

6. Insert a sheet of paper between the edge guides until the bottom

meets resistance. Slide the edge guides to exactly match the width of

your paper.

7.

Press

the LOAD/EJECT

button to automatically feed the single-sheet

paper to the loading position. Then, press the

ON LINE

button to set

the printer on line.

2 - 2 0

Paper Handling

Summary of Contents for ActionPrinter 4500

Page 1: ...4000111 C01 00 ...

Page 8: ...PC 860 Portugal PC 863 Canada French Product Update Notice 7 ...

Page 10: ...EPSON amP 4 5 0 0 User s Manual ...

Page 156: ...The Cut Sheet Feeder 2 Remove the printer cover 5 18 Using the Printer Options ...

Page 292: ...Appendix Proportional Width Table A 2 Character Tables A 6 A l ...

Page 312: ...EPSON qampti 4 5 0 0 Quick Reference ...

Page 316: ...edge guides DIP switch paper tension unit push tractor ...