General Description

Laser 1000/1500 Service Manual

1.4.6 Optional Memory

If you have difficulty printing complex,

pages of you regularly use

downloaded fonts,

you may need

to

sets

on this printer’s

controller board. The printer’s

board comes

either

of RAM installed (for the

1000) or

of RAM installed (for

1500). Two

types of RAM chip sets are available.

RAM chip set

Each set contains four 256K bit

x

4,80

DRAM 20-pin DIP chips

RAM chip set

Each set contains four 1 Mbit

x

4,80

DRAM 20-pin DIP chips

By installing RAM chip sets, you can increase the printer’s memory to a total of

(for the

1000) or

(for

1500), including the resident

memory.

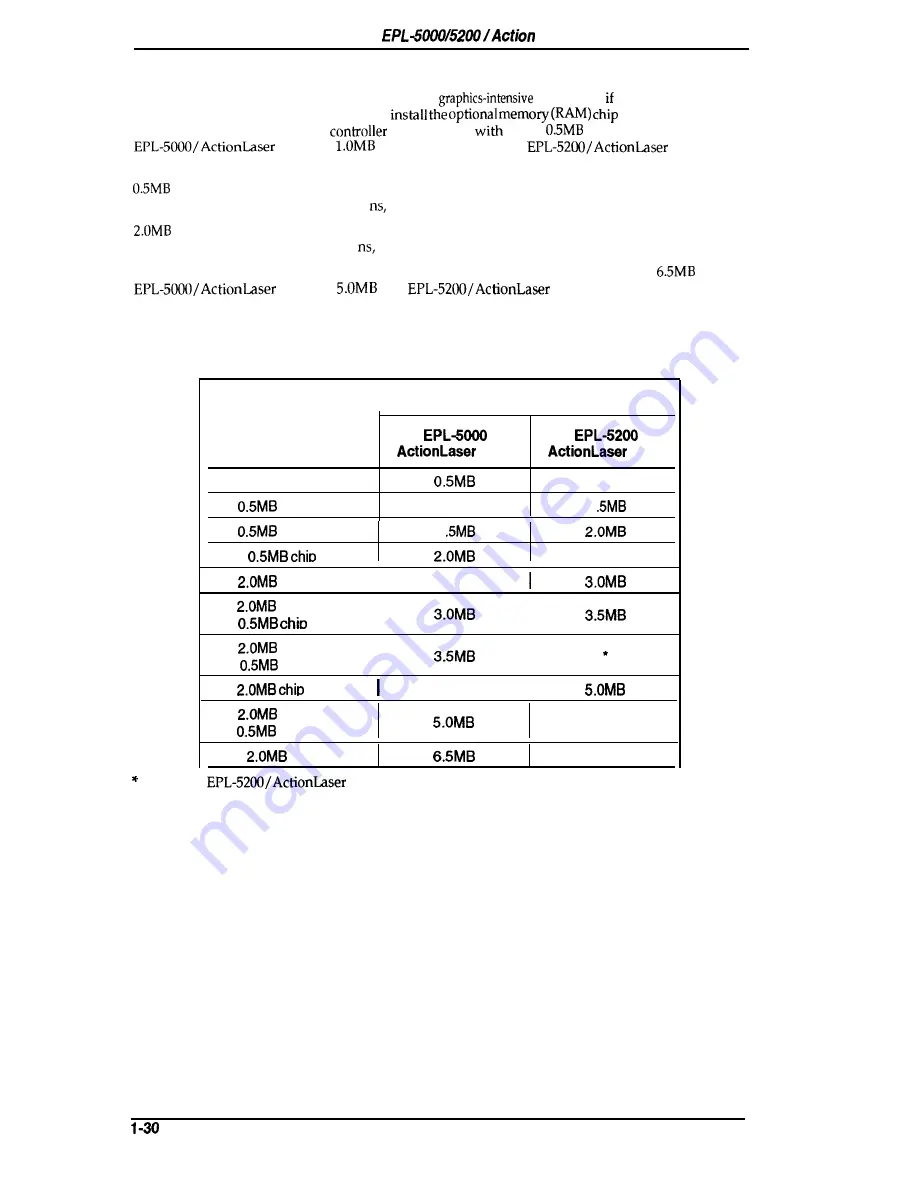

The table below describes the RAM chip combinations.

Table 1-18. RAM Chip Combinations

I

Total RAM

Chip

Set Installed

1000

1500

No chip sets

1.OMB

One

chip set

1.OMB

1

Two

chip sets

1

Three

sets

●

One

chip set

I

2.5MB

One

chip set

One

set

I

I

One

chip set

I

I

Two

chip sets

Two

sets

4.5MB

I

Two

chip sets

*

One

chip set

Three

chip sets

*

On the

1500, one 0.5 MB chip set is initially installed, so you can add

only two more optional chip sets.

Rev. A