Epson Stylus Photo R280/R285/R290/Epson Artisan 50/Epson Stylus Photo T50/T59/T60/P50

Revision C

Chapter 5 Adjustment

5.3 Banding Reduction System (BRS) Adjustment / Paper Feed Amount Profile (PFP) Correction

115

Confidential

5.3 Banding Reduction System (BRS) Adjustment /

Paper Feed Amount Profile (PFP) Correction

5.3.1 Overview

This section explains how to carry out BRS/PFP adjustments.

Tools and paper required to perform the adjustment

Specified Scanner to perform the adjustment

The following are the scanners that can be used for scanning the pattern in BRS/PFP

adjustment. When starting up the adjustment program, select the scanner to use.

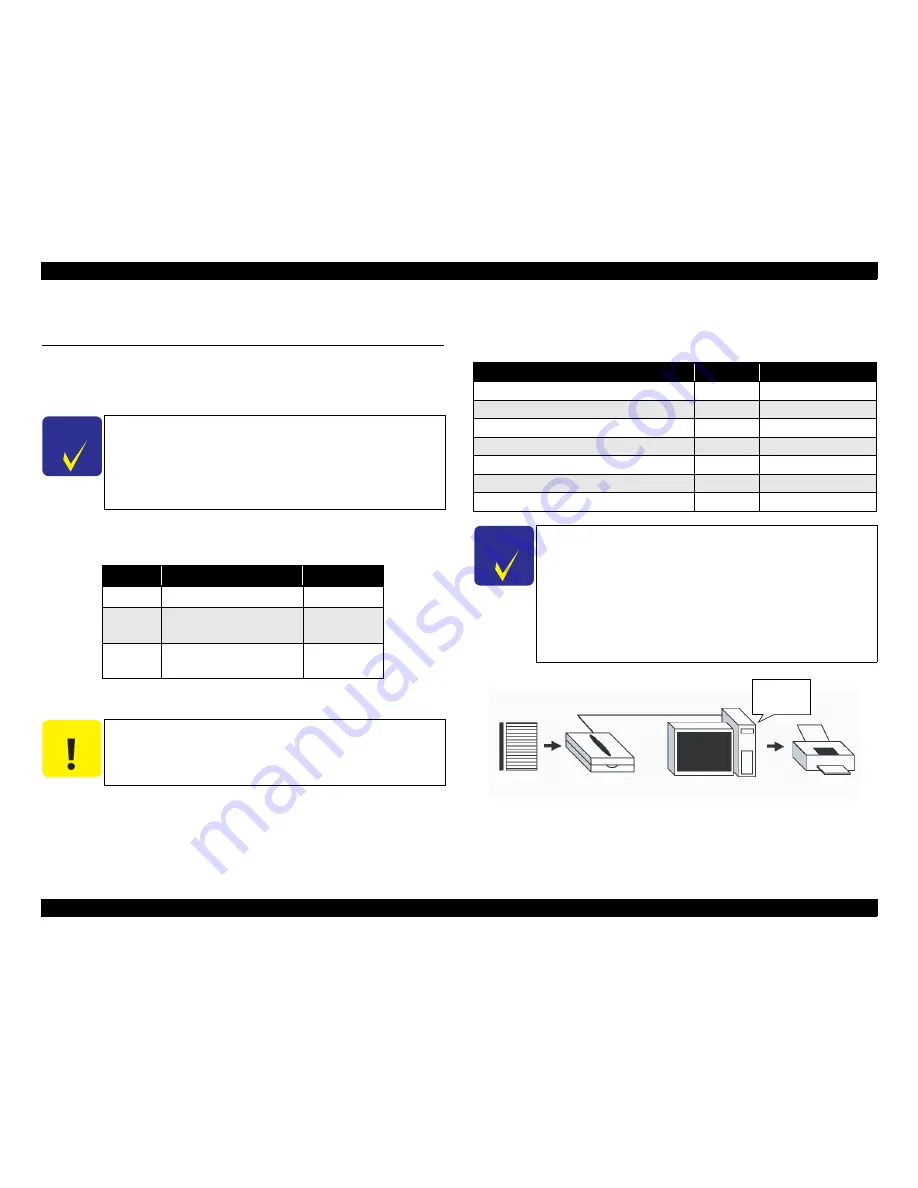

Figure 5-11. System Configuration

C H E C K

P O I N T

For overview of BRS/PFP Adjustment,

refer to Chapter 2

“2.2

Banding Reduction System (BRS) / Paper Feed Amount Profile

Correction (PFP)

(p.25)

Be sure to have a specified scanner ready beforehand as it is

necessary to carry out the adjustment. Before scanning,

confirm that the document table is free from any dirt or stain.

Table 5-6. Tools and Paper for BRS/PFP Adjustment

Tools/Paper

Product Code

Common

PFP Base scale

1453980

BRS

Matte Paper-Heavyweight

(A4)

---

PFP

Premium Glossy Photo Paper

(4 x 6)

---

C A U T I O N

Install the driver of the scanner to the PC in advance.

As the profile required for the adjustment is not prepared for

scanners other than the ones specified below, BRS/PFP

Adjustment can not be carried out by the other scanners.

Table 5-7. Specified Scanner for BRS/PFP Adjustment

Model Name

Sensor type

Remarks

Epson Perfection 4990 Photo

CCD

Epson Perfection V700 Photo

CCD

Epson Stylus Photo RX560/RX580/RX590

CIS

Use the internal scanner.

Epson Stylus Photo RX585/RX595/RX610

CIS

Use the internal scanner.

Epson Stylus Photo RX680/RX685/RX690

CIS

Use the internal scanner.

Artisan 800/Epson Stylus Photo PX800FW/TX800FW

CIS

Use the internal scanner.

Artisan 700/Epson Stylus Photo PX700W/TX700W

CIS

Use the internal scanner.

C H E C K

P O I N T

Depending on the sensor type of the scanner to use for the

adjustment, drying time required after the BRS adjustment

pattern has been printed differs. For PFP adjustment pattern/PFP

check pattern, drying time is not required.

For “CCD” sensor:

Printed pattern can be scanned straight away. (Drying time of

about 2 minutes is recommended.)

For “CIS” sensor:

Printed pattern needs to be dried more than 5 minutes.

Calculate

correction

value

Test Pattern

Scanner

PC

Printer

Summary of Contents for 50 - Artisan 50 - Printer

Page 8: ...Confidential C H A P T E R 1 PRODUCTDESCRIPTION ...

Page 22: ...Confidential C H A P T E R 2 OPERATINGPRINCIPLES ...

Page 29: ...Confidential C H A P T E R 3 TROUBLESHOOTING ...

Page 52: ...Confidential C H A P T E R 4 DISASSEMBLY ASSEMBLY ...

Page 103: ...Confidential C H A P T E R 5 ADJUSTMENT ...

Page 120: ...Confidential C H A P T E R 6 MAINTENANCE ...