Page 42

I.L. 17562

PR 0.3 Effective 8/99

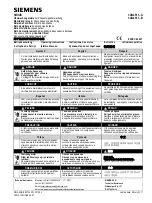

Table 4.5 Log Mode Display

Page

Line

Value

Complete Help Message

Description

LOG

LOG OF EVENTS MODE

Recalls stored motor events as

observed by the relay

LOG

BOOK

LOG BOOK OF THE LAST 100

EVENTS

This page contains a chronological

list of motor events

START

START EVENT – A STOP TO

START TRANSITION WAS

MADE

First event recorded – this is just an

example, the event could be any of

the following six types: start, stop,

entering in program mode,

emergency override, alarm

condition, or trip condition. The

events listed in the Line column are

used to show all of the different

types of events, but a true LOG

BOOK page will have any number

of different events in the order that

they occur. From the LOG BOOK

display, push line up to see the

latest event. Push again for the

next most recent event and so on.

From the LOG BOOK display, push

line down to see the oldest logged

event. Push again to see the next

oldest and so on.

MM/DD/YY

DATE OF EVENT

The date that the event occurred

HH.MM

TIME OF EVENT

The time that the event occurred

STOP

STOP EVENT - A TRANSITION

TO THE STOP STATE WAS

MADE

MM/DD/YY

DATE OF EVENT

The date that the event occurred

HH.MM

TIME OF EVENT

The time that the event occurred

EMRG OVR

EMERGENCY OVERRIDE

EVENT – AN EMERGENCY

OVERRIDE WAS PERFORMED

Emergency override can be

activated from the front face plate,

from a programmed discrete input,

or over the communications

network

MM/DD/YY

DATE OF EVENT

The date that the event occurred

HH.MM

TIME OF EVENT

The time that the event occurred

SET CHNG

PROGRAM MODE ENTERED –

POSSIBLE SET POINT

CHANGES

Recorded every time the program

mode is normally exited. This can

occur with the second push of the

“Prog” push button or over the

communication network.

MM/DD/YY

DATE OF EVENT

The date that the event occurred

HH.MM

TIME OF EVENT

The time that the event occurred

RESET

RESET EVENT – A RESET

EVENT CLEARED A TRIP OR

ALARM

Logged only when a trip or alarm

event was cleared. This can be

done through the front face panel

“Reset” button, by a programmed

discrete input activation, or over

Summary of Contents for 66D2032G01

Page 18: ...Page 18 I L 17562 PR 0 3 Effective 8 99 Figure 4 1 MP 3000 Pushbuttons...

Page 19: ...I L 17562 Page 19 PR 0 3 Effective 8 99 Figure 4 2 MP 3000 LED Indicators...

Page 72: ...Page 72 I L 17562 PR 0 3 Effective 8 99 Figure 6 1 Panel Cutout Dimensions...

Page 73: ...I L 17562 Page 73 PR 0 3 Effective 8 99 Figure 6 2 Faceplate Dimensions...

Page 74: ...Page 74 I L 17562 PR 0 3 Effective 8 99 Figure 6 3 MP 3000 Case Depth Dimensions...

Page 75: ...I L 17562 Page 75 PR 0 3 Effective 8 99 Figure 6 4 Universal RTD Module Mounting Dimensions...

Page 76: ...Page 76 I L 17562 PR 0 3 Effective 8 99 Figure 6 5 Rear Panel Terminals...

Page 78: ...Page 78 I L 17562 PR 0 3 Effective 8 99 Figure 6 7 Typical ac Supply and URTD Wiring...

Page 79: ...I L 17562 Page 79 PR 0 3 Effective 8 99 Figure 6 8 Alternatives for Discrete Input Wiring...

Page 80: ...Page 80 I L 17562 PR 0 3 Effective 8 99 Figure 6 9 RTD Wiring to URTD Module...

Page 100: ...Page 100 I L 17562 PR 0 3 Effective 8 99 Figure 9 1 Rotor Temperature Tracking...

Page 101: ...I L 17562 Page 101 PR 0 3 Effective 8 99 Figure 9 2 Motor Protection Curve...

Page 102: ...Page 102 I L 17562 PR 0 3 Effective 8 99 Figure 9 3 Underload Jam Protection Curve...

Page 104: ...Page 104 I L 17562 PR 0 3 Effective 8 99 Figure 9 5 Motor Protection Curve Example with RTDs...

Page 105: ...I L 17562 Page 105 PR 0 3 Effective 8 99 Figure 9 6 Motor Start and Run Cycles...

Page 109: ...I L 17562 Page 109 PR 0 3 Effective 8 99 P5L8 40 Incomplete Sequence time 1 60s OFF 1 240s...