OP000529

3-8

Operation

Starting Engine With a Booster Cable

If the batteries are drained during starting procedures, jump start

engine using auxiliary or booster batteries according to the

following procedure;

Connecting the Booster Batteries

1.

Shut down engine of the machine on which booster

batteries (3, Figure 15) are mounted.

2.

Connect one end of red cable (1, Figure 15) to the positive

(+) terminal of the machine batteries (4), and the other end

to the positive (+) terminal of the booster batteries.

3.

Connect one end of black cable (2, Figure 15) to the

negative (-) terminal of the booster batteries (3), and then

make ground connection to the upper frame (5) of the

machine to be started with the other end of black (-) cable

(2, Figure 15). When making the last connection to upper

frame, be sure to connect the cable end as far away from

HAOA440L

Figure 14

WARNING!

1.

An explosive gas is produced while batteries are in

use or being charged. Keep flames or sparks away

from the battery area.

2.

Charge batteries in a well ventilated area.

3.

Always wear eye protection when starting a machine

with jumper cables.

4.

Improper jump starting procedures can cause an

explosion resulting in personal injury.

5.

Jump start vehicles on dry ground or concrete. Do not

jump start the machine on a steel floor, because the

floor is always grounded.

6.

When starting from another machine, make sure the

machines do not touch.

7.

Always connect the auxiliary battery positive (+)

terminal too depleted battery positive (+) terminal first.

Then connect auxiliary battery negative (-) terminal to

the frame of the depleted battery machine second.

8.

Connect positive cable first when installing cables and

disconnect the negative cable first when removing.

IMPORTANT

The machine has a 24V (-) negative ground electrical

system. Use the same capacity 24V booster batteries when

jump starting engine.

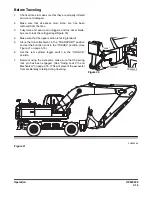

1

4

5

3

2

RED

BLACK

ARO0440L

Figure 15

Summary of Contents for DX190W

Page 2: ......

Page 71: ...OP000528 2 3 Operating Controls ...

Page 128: ...OP000528 Operating Controls 2 60 CD Player Optional AST DIR FG000109 Figure 135 ...

Page 196: ......

Page 292: ...OP000530 Inspection Maintenance and Adjustment 4 96 ...

Page 304: ...OP000440 6 8 Troubleshooting ...