OP000529

3-46

Operation

OPERATING TECHNIQUES

Lifting

To prevent injury, do not exceed the rated load capacity of the

machine. If the machine is not on level ground, load capacities

will vary.

Short slings will prevent excessive load swing.

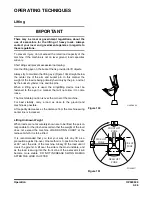

Use the lifting eye on the bucket that is provided to lift objects.

Always try to maintain the lifting eye (Figure 100) straight below

the center line of the arm and bucket pin. In this manner the

weight of the load is being primarily held only by the pin, and not

by the bucket cylinder, link, and link pins.

When a lifting eye is used, the sling/lifting device must be

fastened to the eye in a manner that will not allow it to come

loose.

The most stable position is over the corner of the machine.

For best stability, carry a load as close to the ground and

machine as possible.

Lift capacity decreases as the distance from the machine swing

center line is increased.

Lifting Unknown Weight

When loads are not accurately known are to be lifted, the person

responsible for the job shall ascertain that the weight of the load

does not exceed the machine LOAD RATING CHART at the

radius at which it is to be lifted.

It is recommended that you feel your way into any lift as a

precaution against tip-over. One method is to position the boom

at 90° over the side of the machine. Slowly lift the load until it

clears the ground. A lift over the side is the most unstable, and

as the load is swung into the front zone of the excavator it will

become more stable. DO NOT INCREASE SWING RADIUS

AFTER THE LOAD IS LIFTED.

IMPORTANT

There may be local or government regulations, about the

use of excavators for the lifting of heavy loads. Always

contact your local and government agencies in regards to

these regulations.

HAAD3830

Figure 100

FG006217

FRONT LIFT

ZONE

SIDE LIFT

ZONE

SIDE LIFT

ZONE

REAR LIFT

ZONE

Figure 101

Summary of Contents for DX190W

Page 2: ......

Page 71: ...OP000528 2 3 Operating Controls ...

Page 128: ...OP000528 Operating Controls 2 60 CD Player Optional AST DIR FG000109 Figure 135 ...

Page 196: ......

Page 292: ...OP000530 Inspection Maintenance and Adjustment 4 96 ...

Page 304: ...OP000440 6 8 Troubleshooting ...