OP000509

4-61

Inspection, Maintenance and Adjustment

Replace Hydraulic Full Flow Filter

NOTE:

Replace hydraulic full flow filter after first 50 hours of

operation or rebuild and every 1000 Hours thereafter.

1.

Loosen breather cap on hydraulic tank. (See Figure 20

on page 4-25).

2.

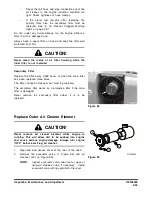

Clean filter cover (2, Figure 97) and tank around cover.

3.

Remove bolts (1, Figure 97) from cover (2).

4.

Lift cover (2, Figure 97) and O-ring (4) off tank. A

control spring (3) sits beneath cover. Remove spring

(3).

5.

Remove valve (5, Figure 97) and filter (6) from tank.

6.

Clean underside of cover (2, Figure 97).

7.

Set a new element (6, Figure 97) and valve (5) down

into tank. Press element down onto its base until top of

element is approximately 4 mm (0.157") below edge of

tank.

8.

Install a new O-ring (4, Figure 97) on cover (2). Set

spring (3) into place on element (6).

9.

Set cover (2, Figure 97) into place over element (6).

Install bolts (1) through cover (2) and tighten them.

10.

Tighten breather cap on tank.

WARNING!

The hydraulic oil will be hot after normal machine

operation. Allow system to cool before attempting to

service any of the hydraulic components.

The hydraulic tank is pressurized. Loosen hydraulic oil

fill cap slightly to allow pressurized air to vent. After

pressure has been released, it is safe to remove either

the fill cap or service covers or drain water from the

tank.

IMPORTANT

Make sure to clean any dirt or water from top of the

hydraulic tank, especially around fill port and filter

ports.

2

1

6

5

4

3

FG006233

Figure 97

Summary of Contents for DL200

Page 2: ......

Page 6: ...K1024537E Table of Contents IV ...

Page 7: ...K1024537E I I Presentation 1Presentation PRESENTATION FG008047 Figure 1 ...

Page 17: ...OP000506 1 5 Safety 1 3 10 12 6 4 11 5 9 8 3 7 10 9 4 6 2 FG008049 Figure 1 ...

Page 60: ...OP000506 Safety 1 48 ...

Page 112: ...OP000507 Operating Controls 2 52 CD Player Optional AST DIR FG000109 Figure 101 ...

Page 122: ...OP000507 Operating Controls 2 62 ...

Page 232: ...OP000509 Inspection Maintenance and Adjustment 4 88 ...

Page 242: ...OP000040 Troubleshooting 6 8 ...

Page 252: ...OP000510 Specification 7 10 ...