OP000509

4-9

Inspection, Maintenance and Adjustment

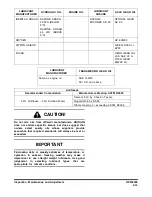

NOTE:

If a high-pressure jet is used for cleaning, take great

care as the insulation of electric leads can be

damaged even at a moderately high-pressure and

temperature. Protect electrical leads in an

appropriate way.

Take extra care when cleaning the machine after it has been

used in a fire sensitive environment, e.g. sawmill and refuse

dumps. Reduce the risk of spontaneous combustion by

installing for example silencer guard or high capacity cyclone

precleaner.

Sound absorbing material in the engine compartment must

be kept clean to minimize the fire hazard.

Fire prevention equipment which is installed on the machine

must be maintained and regarded as a complement to the

actions of the operator in case of a fire.

Check that fuel lines, hydraulic and brake hoses and

electrical cables have not been damaged by chafing or are

not in danger of being damaged because of incorrect

installation or clamping. This applies particularly to unfused

cables, which are red and marked R(B+) and routed:

•

between the batteries

•

between battery and starter motor

•

between alternator and starter motor

•

to the preheating element on the engine.

Electrical cables must not lie directly against oil or fuel lines.

The following applies for welding and grinding work:

•

A fire extinguisher must be kept near at hand.

•

The ventilation must be good when working indoors.

•

Approved respirator must be used

•

The work surface must be cleaned.

•

Do not weld or grind on components which are

filled with flammable liquids, e.g. tanks and

hydraulic pipes. Exercise care with such work in

the proximity of these places.

Working on Painted Surfaces

When welding, grinding and gas cutting, the paint finish

must first be removed from an area with a radius of at least

10 cm (4 in) from the point where the work is to be carried

out. The reason for this is that paint when heated gives off

a great number of different substances which can cause

irritation and be very harmful to a person's health in case of

long or frequent exposure.

In addition to the health hazard, the weld will also be of an

inferior quality and strength, which in the future may cause the

weld to break. Therefore, never weld directly on a painted surface.

Summary of Contents for DL200

Page 2: ......

Page 6: ...K1024537E Table of Contents IV ...

Page 7: ...K1024537E I I Presentation 1Presentation PRESENTATION FG008047 Figure 1 ...

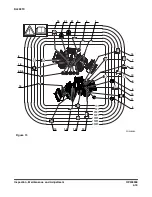

Page 17: ...OP000506 1 5 Safety 1 3 10 12 6 4 11 5 9 8 3 7 10 9 4 6 2 FG008049 Figure 1 ...

Page 60: ...OP000506 Safety 1 48 ...

Page 112: ...OP000507 Operating Controls 2 52 CD Player Optional AST DIR FG000109 Figure 101 ...

Page 122: ...OP000507 Operating Controls 2 62 ...

Page 232: ...OP000509 Inspection Maintenance and Adjustment 4 88 ...

Page 242: ...OP000040 Troubleshooting 6 8 ...

Page 252: ...OP000510 Specification 7 10 ...