OP000509

4-17

Inspection, Maintenance and Adjustment

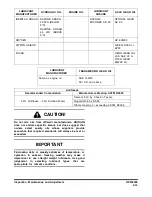

LUBRICATION AND SERVICE

CHART

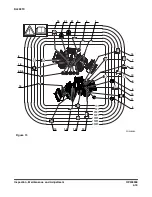

Greasing Bearing

The service life of bushings and pivot pins can be extended

considerably, if the machine is greased regularly and in the

correct way.

The greasing of bearings has two main purposes:

•

Add grease to the bearing to reduce friction

between pin and bushing.

•

Replace old grease which may contain dirt. The

grease in the space inside the outer seal collects

dirt and prevents dirt and also water from

penetrating into the bearing.

Therefore, grease the bearing until new, clean grease is

forced out through the outer seal.

Between 10 and 15 strokes with a normal handheld grease

gun is required to grease one of the bearings for the lifting

arms.

Wipe off grease fittings and grease gun before greasing, so

that dirt and sand is not introduced through the grease

fittings.

Symbol key

These standard symbols are used in “Lubrication and

Service Chart” on page 4-18.

Symbol

Description

Symbol

Description

Lubrication

Air Cleaner Element

Transmission Oil

Fuel Filter

Engine Oil

Air Conditioner Filter

Engine Oil Filter

Drain Water

Hydraulic Oil

Gear Oil (Axle)

Hydraulic Oil Return Filter

Brake Filter

Coolant

Level Check

Summary of Contents for DL200

Page 2: ......

Page 6: ...K1024537E Table of Contents IV ...

Page 7: ...K1024537E I I Presentation 1Presentation PRESENTATION FG008047 Figure 1 ...

Page 17: ...OP000506 1 5 Safety 1 3 10 12 6 4 11 5 9 8 3 7 10 9 4 6 2 FG008049 Figure 1 ...

Page 60: ...OP000506 Safety 1 48 ...

Page 112: ...OP000507 Operating Controls 2 52 CD Player Optional AST DIR FG000109 Figure 101 ...

Page 122: ...OP000507 Operating Controls 2 62 ...

Page 232: ...OP000509 Inspection Maintenance and Adjustment 4 88 ...

Page 242: ...OP000040 Troubleshooting 6 8 ...

Page 252: ...OP000510 Specification 7 10 ...