OP000509

Inspection, Maintenance and Adjustment

4-12

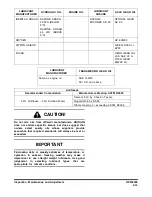

PREVENTIVE MAINTENANCE

Periodic checks and replacement of oil, grease, filters, etc.

must be made at specific intervals, to keep machine in good

working condition. The following pages describe items to be

checked, lubricants to be used, and time interval between

each check.

NOTE:

Time interval between each service check may need

to be shortened if machine is operating in severe

atmospheric conditions. Machines working in

extremely hot or dusty conditions will require more

frequent service checks. Total hours of machine

operation are determined by hour meter that is on the

front instrument panel.

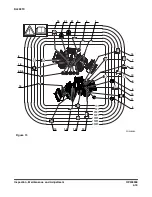

Product Identification Number (P. I. N.)

Location

The PIN is stamped on the product identification plate

(Figure 9) on the right side of front frame above wheel

cover.

NOTE:

Please make note of these numbers and their

locations. These will be required whenever warranty

or service work is requested. Keep this number on

file, in case the mathine is stolen.

Figure 8

HAOA600L

K1011647B

K1011647B

Incheon, Korea

7-11, Hwasu-dong, Dong-gu,

FG008057

Figure 9

Summary of Contents for DL200

Page 2: ......

Page 6: ...K1024537E Table of Contents IV ...

Page 7: ...K1024537E I I Presentation 1Presentation PRESENTATION FG008047 Figure 1 ...

Page 17: ...OP000506 1 5 Safety 1 3 10 12 6 4 11 5 9 8 3 7 10 9 4 6 2 FG008049 Figure 1 ...

Page 60: ...OP000506 Safety 1 48 ...

Page 112: ...OP000507 Operating Controls 2 52 CD Player Optional AST DIR FG000109 Figure 101 ...

Page 122: ...OP000507 Operating Controls 2 62 ...

Page 232: ...OP000509 Inspection Maintenance and Adjustment 4 88 ...

Page 242: ...OP000040 Troubleshooting 6 8 ...

Page 252: ...OP000510 Specification 7 10 ...