OP000509

Inspection, Maintenance and Adjustment

4-26

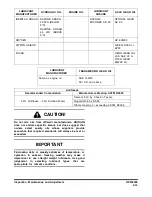

2.

Check O-ring for damages and replace if necessary.

Check position of O-ring at surface of hole.

3.

Place the cover on the access hole. Make sure the

spring retaining cup (1, Figure 22) in the lower section

of the cover is lined up with the spring. The filter

assembly rod must be in a vertical position and

perpendicular to the base of the tank. The cover can

be rotated to align the rod into a vertical position.

4.

Tighten mounting bolts to 4.84 kg•m (35 ft lb).

Check for Leaks in Hydraulic System

1.

Perform a daily walk-around inspection to make sure

that the hoses, piping, fittings, cylinders and hydraulic

motors are not showing any signs of leakage. If any is

noted, determine the source of the leak and repair.

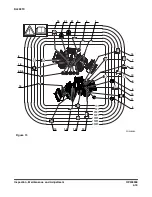

Fill Fuel Tank

1.

At end of each work day, fill fuel tank. Add fuel

through fuel fill cap (Figure 23). When working at a

temperature of 0°C (32°F) or higher, use ASTM No.

2-D or its equivalent. At temperatures below 0°C (32°F)

use ASTM No. 1-D or its equivalent.

2.

Securely tighten cap after fueling.

NOTE:

If breather holes in cap are clogged, a vacuum

may form in the tank preventing proper fuel flow

to engine. Keep holes in fuel cap clean.

Figure 22

FG002189

1

FG001689

Figure 23

WARNING!

Use extreme safety precautions while refueling to prevent

explosions or fire.

Immediately clean up any spilt fuel.

FG001690

Figure 24

Summary of Contents for DL200

Page 2: ......

Page 6: ...K1024537E Table of Contents IV ...

Page 7: ...K1024537E I I Presentation 1Presentation PRESENTATION FG008047 Figure 1 ...

Page 17: ...OP000506 1 5 Safety 1 3 10 12 6 4 11 5 9 8 3 7 10 9 4 6 2 FG008049 Figure 1 ...

Page 60: ...OP000506 Safety 1 48 ...

Page 112: ...OP000507 Operating Controls 2 52 CD Player Optional AST DIR FG000109 Figure 101 ...

Page 122: ...OP000507 Operating Controls 2 62 ...

Page 232: ...OP000509 Inspection Maintenance and Adjustment 4 88 ...

Page 242: ...OP000040 Troubleshooting 6 8 ...

Page 252: ...OP000510 Specification 7 10 ...