RF Baghouse, Models RFWP and RFWPH

60

Electrical installation, service,

or maintenance work must be

performed by a qualified electrician and comply

with all applicable national and local codes.

Turn power off and lock out electrical

power sources before performing service or

maintenance work.

Do not install in classified hazardous

atmospheres without an enclosure rated for the

application.

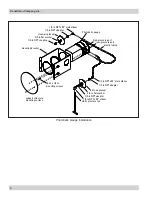

The Photohelic combines the functions of a differential

pressure gauge and a pressure-based switch. The gauge

function measures the pressure difference between the

clean-air and dirty-air plenums and provides a visual display

of filter condition. The high-pressure tap is located in the

dirty-air plenum and a low-pressure tap is located in the

clean-air plenum. The pressure-based switch function provides

high-pressure ON and low-pressure OFF control of the filter

cleaning system.

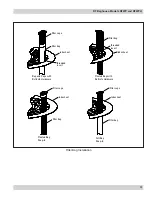

1. Choose a convenient, accessible location on or near

the collector for mounting that provides the best visual

advantage.

2. Mount the gauge to the remote panel or door using the

mounting ring, retaining ring, and four #6-32 x 1 1/4-in

screws. Do not tighten screws. Connect two, 1/8-in NPT x

1/4-in OD male adapters to the gauge’s high- and low-

pressure ports. Tighten screws.

3. On the back of the gauge, remove four #6-32 x 5/16-in

screws and plastic enclosure. Set aside. Add two jumper

wires supplied by customer. Remove the jumper from the

pressure switch located on the timer board, if equipped.

Using the 3/4-in conduit opening, wire the gauge as

shown. Reassemble and fasten enclosure securely.

4. Thirty-five feet of plastic tubing is supplied and must be

cut in two sections. Connect one section of tubing from the

gauge’s high-pressure port to the pressure fitting located

in the dirty-air plenum. Connect remaining tubing from

the gauge’s low-pressure port to the fitting in the clean-

air plenum. Additional tubing can be ordered from your

representative.

5. Zero and maintain the gauge as directed in the

manufacturer’s Operating and Maintenance Instructions

provided.

6. To install the Photohelic Gauge mounted in a NEMA 4,

Weatherproof Enclosure, follow Steps 4 and 5.

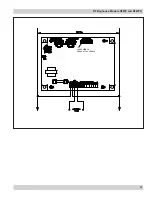

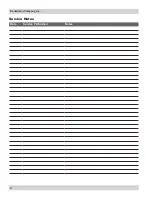

Photohelic gauge

solenoid

valves

Pressure Switch

terminals

neutral

110-V

jumper wires

supplied by customer

timer

board

L1 L2

1 2 3

sol

com

L2

L1

HI

LO

C NO

NC

NC NO C

C NO NC NC NO C

Photohelic Gauge Wiring Diagram

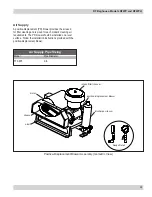

Photohelic Gauge in Optional NEMA 4

Weatherproof Enclosure

Note:

For use with solid-state timer only. All parts, except

the mounting bracket shown in the Photohelic Gauge

Standard Installation drawing are included with the

NEMA 4, Weatherproof Enclosure.

Photohelic

®

Gauge