45

Donaldson Company, Inc.

4. Apply hardware adhesive to the 3/8-in hardware and

tighten the Centering Plate to the tube sheet plate. If the

Centering Plate will not align with a bolt location on the

tube sheet plate, the assembly is out of alignment and

needs to be fixed by repeating step 3. Check rotation of

the arms and repeat this step if necessary.

Note: Repositioning of the air tank assembly may be

required for this step to ensure the cleaning arms

can rotate freely.

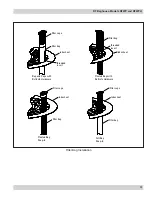

5. Install the gear reducer and sprocket along with the

chain tensioner to the H-Frame (reference the included

Cleaning Assembly drawing AD3627301 or AD3627302

depending on size).

Note: Drive sprocket, tensioner, and idler sprocket

must lie in the same plane. Adjust driver sprocket

and chain tensioner to achieve results.

6. Connect the chain from the drive sprocket to the rotating

assembly using the master link.

7. Install motor to the gear reducer. Check that the motor

shaft key is in place and enters the keyway in the gear

drive correctly. Fasten the motor flange to the gear

reducer housing using the four hex head cap screws

supplied.

8. Ensure the gearbox has been prefilled with lubricant.

9. Remove the top pipe plug and install the breather.

10. Remove the plastic exhaust-port plug from the bottom of

the solenoid valve.

11. Adjust the drive sprocket, tensioner sprocket and idler so

they are in the same horizontal plane.

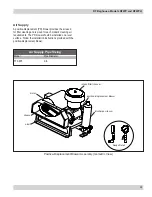

12. Wire the motor to a customer-supplied motor starter with

overload and short circuit protection.

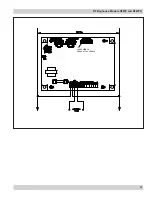

Electrical Wiring

Electrical installation, service,

or maintenance work must be

performed by a qualified electrician

and comply with all applicable national and local

codes.

Turn power off and lock out electrical

power sources before performing service or

maintenance work.

Do not install in classified hazardous

atmospheres without an enclosure rated for the

application.

All electrical wiring and connections, including electrical

grounding, should be made in accordance with the National

Electric Code (NFPA No. 70-latest edition).

Check local ordinances for additional requirements that apply.

The appropriate wiring schematic and electrical rating must be

used. See collector’s rating plate for required voltage.

An electric disconnect switch having adequate amp capacity

shall be installed in accordance with Part IX, Article 430 of the

National Electrical Code (NFPA No. 70-latest edition). Check

collector’s rating plate for voltage and amperage ratings.

Refer to the wiring diagram for the number of wires required for

main power wiring and remote wiring.

If the collector was supplied with an electrical

control panel, the wiring diagram supplied with

the control panel takes precedence over the

general diagrams shown in this manual.