RF Baghouse, Models RFWP and RFWPH

54

Instruct all personnel on safe use and maintenance

procedures.

Use proper equipment and adopt

all safety precautions needed for

servicing equipment.

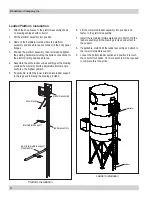

Use appropriate access equipment and

procedures. Note the standard collector is not

equipped with access platforms unless noted on

the specification drawings.

Electrical service or maintenance work must be

performed by a qualified electrician and comply

with all applicable national and local codes.

Turn power off and lock out electrical

power sources before performing service or

maintenance work.

Do not install in classified hazardous

atmospheres without an enclosure rated for the

application.

Maintenance Information

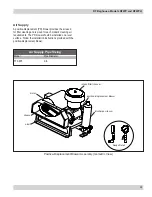

Turn positive displacement pump OFF and bleed lines and

tank before performing service or maintenance work.

Operational Checklist

1. Monitor the physical condition of the collector and repair or

replace any damaged components.

Routine inspections will minimize downtime and maintain

optimum system performance. This is particularly

important on continuous-duty applications.

Periodically check the positive displacement pump

components and replace filters as required to maintain

blower pressure rating. Check rotation of cleaning arms.

2. Monitor pressure drop across filters.

Abnormal changes in pressure drop may indicate a

change in operating conditions and possibly a fault to be

corrected.

4. Monitor exhaust.

5. Monitor dust disposal.

Weekly

1. Check that pressure drop is within normal operational

range (from 1 to 6 "wg).

2. Check for proper air pressure at reservoir (8 psi for 570-

608 collectors and 9 psi for all larger collectors).

3. Check for proper lubricant level in positive-displacement

blower.

Quarterly

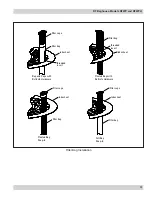

1. Check condition of the clean-air plenum. If dust

accumulation is present, check filter bags for wear, tears

or loose seals. Replace as necessary.

2. On high inlet collectors, check the condition of the

removable baffle weld assembly by removing the side

access cover on the baffle housing. Replace significantly

worn baffle assemblies to prevent damage to the filter

tubes and housing section.

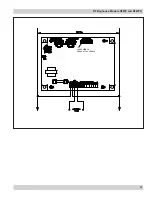

3. Check solenoid and diaphragm valve operation.

4. Check door seals and replace as necessary.

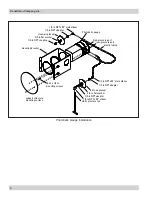

5. Check cleaning arm drive chain and positive-

displacement blower belt tension.

6. Check positive-displacement blower and gear reducer oil

levels. Add oil through breather mounting holes or other

oil fill locations. Reference the blower owner’s manual for

proper lubricant.

0°F-32°F - use ISO 68 lubricant

32°F-90°F - use ISO 100 lubricant

90°F-120°F - use ISO 150 lubricant

7. Inspect explosion vents, if applicable, for signs of wear or

cracks.

8. Check the rotating arm manifold drive gear reducer oil

level. Add oil through breather mounting holes or other

oil fill locations. The gear reducer is filled with synthetic

oil. See reducer manual for recommended lubrication

type and quantity. When checking or replacing the oil,

make sure to check both housings of the double reduction

reducer. Each housing has its own vent, fill and drain

plug.