01/2018

63 / 80

6159933780

Issue no: 09

CVIL II

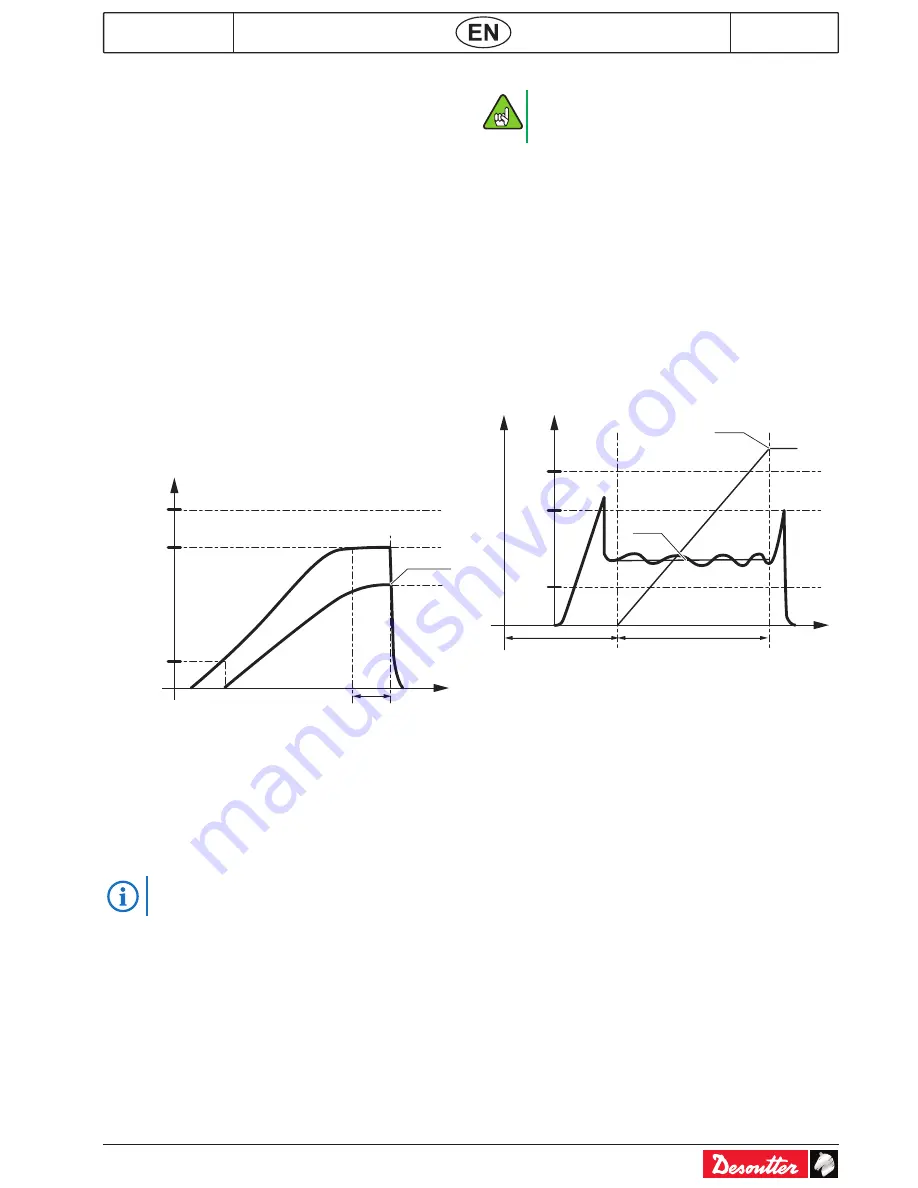

11.5 - Stall torque controlled tightening

This tightening strategy is used to check the tuning of

a tightening unit in static mode with the possibility of

monitoring the linearity of its torque transducer.

The stall torque tightening is also used when you want to

keep a constant torque on a joint, either to compensate

a creep in a seal, or to keep a load on a joint during a

complex operation.

During this phase, as long as the motor has not reached

its torque value, the motor is controlled on the speed

loop.

When the stall torque is reached, the torque control and

stall are performed on the current loop.

The stall time can be set between 0.1 and 10 seconds.

To avoid the overheating of the motor, in this type of

application it is recommended to oversize the tightening

unit.

The thermal contact located in the motor provides

protection in case of overheating.

The max. torque must be programmed to a value higher

than the desired stall torque.

The recorded values are the following: final torque in bolt

and final angle.

Torque

Time

Final

angle

Stall

time

Stall torque

Angle

threshold

Max.

Spindle stop

● IF stall time elapsed

● OR torque > max. torque

● OR angle > max. angle

Accept report

● IF min. torque ≤ final torque ≤ max. torque

● IF min. angle ≤ final angle ≤ max. angle

Bandwidth has to be set to 128Hz.

11.6 - Prevailing torque control

In the Pulse mode, the prevailing torque

parameter cannot be higher than the tool max

torque continuous.

This phase allows you to check the residual torque

(prevailing torque) that results, for instance from the

thread formed with tapping screws.

It is useful to know if the thread is formed correctly

during the desired number of rotations without untimely

locking or tapping deficiency.

The initial time out allows you to start the readings when

the tool speed is stabilised.

The memorised result is the mean of the torque readings

during the acquisition phase.

The system stops the acquisition of the torque and angle

when the motor stops.

The torque pulse at the motor stop is not taken into

account.

Torque

Angle

Time

Mean torque

Target angle

Max

Min

Safety

Rise delay

time or angle

Data aquisition

Spindle stop

● IF angle ≥ target angle

● OR torque> safety torque

Accept report

● IF min. torque ≤ torque ≤ max. torque