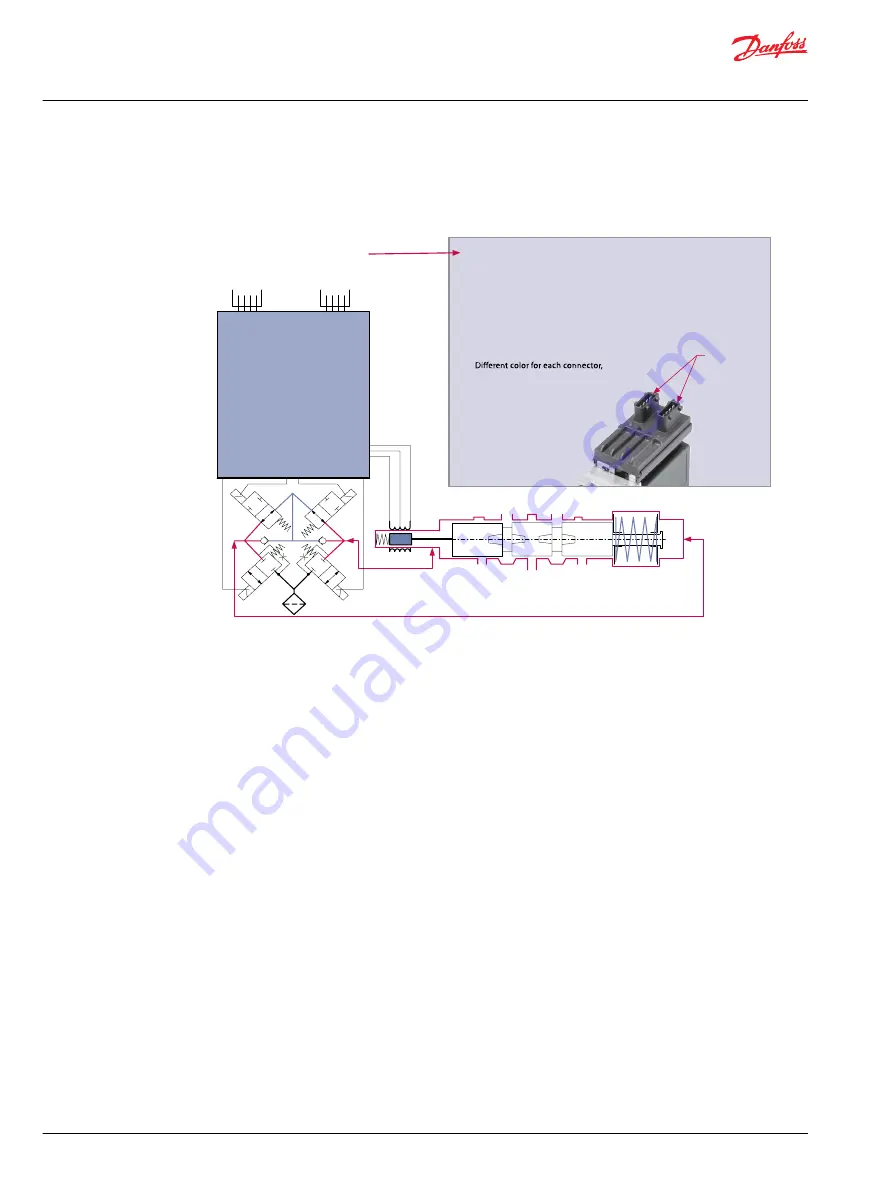

colored differently to distinguish CAN and power supply from cables with analog control signals. When

using AMP the gray connector is dedicated for CAN and electric power supply and the black for

connecting analogue devices to the PVED. Deutsch connectors are not-keyed, but PVED-CL is laser-

marked with description.

AMP connectors

CR

CL

P

T

T

LVDT

Neutral spring

T

P (12bar+T)

Contour of

PVG 32 casting

AMP-connector

(Gray)

AMP-connector

(Black)

2

D

A

5V

t

u

o 1D

A

D

N

G

A

C

N

H_

a

b-

V

t

A

C

N

L_

D

N

G

P005 092E

Electronic Controller Unit

The 4-pin AMP (Junior Power Timer) has been designed especially for the

automotive industries where high reliability and safety is required.

The features of the AMP connectors are:

Separate insulation of each lead ensures minimum risk of short cutting

•

•

Safe JPT locking

•

•

Safe locking of housing

•

•

Mechanical coding of housing

•

•

IP 66

•

•

•

•

which prevents mistakes during installation

Easy disassembly

•

•

Electronic Control Unit

The Electronic Control Unit (ECU) performs the following tasks:

•

CAN messages. The PVED hardware is compatible to CAN 2.0B

•

Converting two analogue input voltages between 0 and 5V to digital signals (10 bit)

•

Executing the steering software & monitoring for discrepancies with fixed time intervals

•

Output the main spool position setpoint

•

Controlling the LED color

Solenoid Valve Bridge

The PVED-CL features an integrated feedback transducer that measures spool movement in relation to

the input signal from the main micro controller, and by means of a solenoid valve bridge, controls the

direction, velocity, and position of the main spool of the valve. The integrated electronics compensate for

flow forces on the spool, internal leakage, changes in oil viscosity, pilot pressure, etc. This results in lower

hysteresis and better resolution.

Control Principle

In principle the input signal (set-point signal) determines the level of pilot pressure, which moves the

main spool. The position of the main spool is sensed in the LVDT transducer, which generates an electric

feedback signal registered by the electronics. The variation between the set-point signal and feedback

signal activates the solenoid valves. The solenoid valves are actuated so that hydraulic pressure drives the

main spool into the correct position.

Operation Manual

PVED-CL Controller for Electro-Hydraulic Steering, Version 1.38

Configuration and Adjustment

20 |

©

Danfoss | May 2016

11025583 | AQ00000216en-US0302