MiniMax

Bolt Tension Monitor

185

2) The

and

arrow keys to scroll through the sub menu items until

DEFAULT SETUP

is highlighted.

3) Press the

key to load default

DEFAULT SETUP

.

4) Finally, press the

key to return to the measurement screen.

15.6 Selecting a Language

The

MiniMax

is equipped with a language option. Currently, only a few languages

supported. However, be sure to update your gauge firmware often, to check for

language additions. The steps to select a language are outlined as follows:

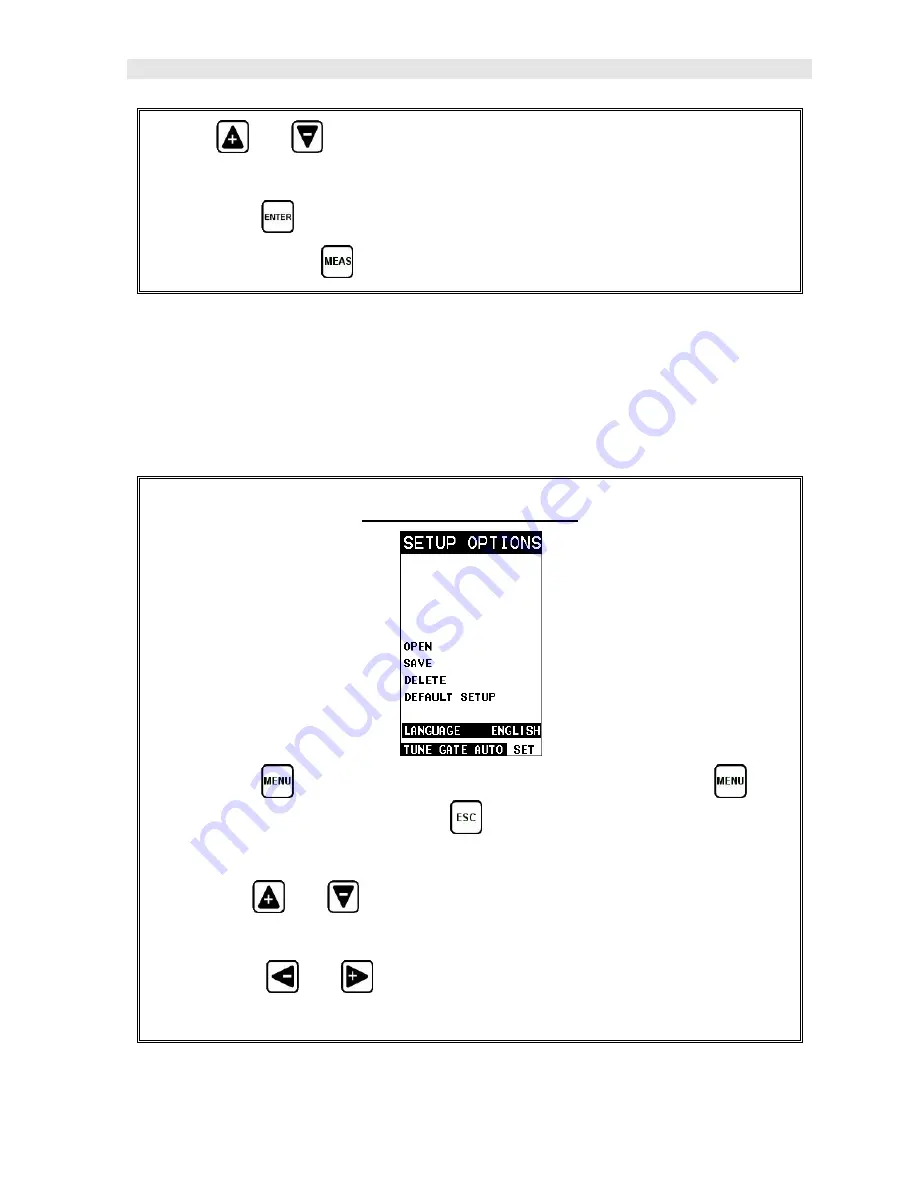

Selecting a Language

1) Press the

key once to activate the menu items tab. Press the

key

multiple times to tab right and the

key multiple times to tab left until the

SETUP

menu is highlighted and displaying the submenu items.

2) Use the

and

arrow keys to scroll through the sub menu items until

LANGUAGE

is highlighted.

3) Press the

and

arrow keys multiple times to toggle the language

options.

Summary of Contents for MiniMax v2.0

Page 2: ......

Page 49: ...MiniMax Bolt Tension Monitor 43 Figure 6 Reflection in a bending bolt...

Page 196: ......