40

J.

Check thermostat or operating control operation

.

Raise and lower temperature setting to start and stop

boiler operation.

K.

Check ignition system shut-off.

1. Honeywell EI: Disconnect ignitor/sensor cable from

ignition module. Gas valve must close and pilot and

main burners extinguish. If not, measure voltage

across gas valve terminals “TH” and “TR”.

a. If voltage is not present, replace gas valve.

b. If voltage is present, replace ignition module.

2. EP: Refer to instructions supplied with the

Honeywell RM7890 Burner Control.

L.

Check Limit(s).

1. Adjust thermostat to highest setting.

2. Observe temperature gauge. When temperature

exceeds limit set point main burners should

extinguish.

3. Adjust limit to setting above observed reading. Main

burners should reignite.

4. Adjust thermostat to lowest setting. Adjust limit to

desired setting.

M.

Adjust gas input rate to boiler

. Natural Gas.

1. Adjust thermostat to highest setting.

2. Check manifold gas pressure. Manifold pressure

is listed on rating label. Adjust gas valve pressure

regulator as necessary (turn adjustment screw

counterclockwise to decrease manifold pressure, or

clockwise to increase manifold pressure). If pressure

can not be attained, check gas valve inlet pressure.

If less than minimum gas supply pressure

listed on rating label, contact gas supplier for

assistance

.

3. Clock gas meter for at least 30 seconds. Use Table

12 to determine gas flow rate in Cubic Feet per

Hour.

4. Determine Input Rate. Multiply gas flow rate by gas

heating value.

Warning

Failure to properly adjust gas input rate will result

in over firing or under firing of the appliance.

Improper and unsafe boiler operation may result.

5. Compare measured input rate to input rate stated on

rating label.

a. Boiler must not be overfired. Reduce input rate

by decreasing manifold pressure. Do not reduce

more than 0.3 inch w.c. If boiler is still overfired,

contact your Crown distributor or Regional

Office for replacement Gas Orifices.

b. Increase input rate if less than 98% of rating

plate input. Increase manifold gas pressure no

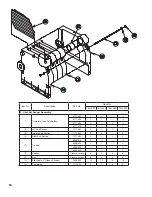

Seconds

for One

Revolution

Size of Gas Meter Dial

One-Half

Cu. Ft.

One

Cu. Ft.

Two

Cu. Ft.

Five

Cu. Ft.

30

60

120

240

600

32

56

113

225

563

34

53

106

212

529

36

50

100

200

500

40

45

90

180

450

38

47

95

189

474

40

45

90

180

450

42

43

86

172

430

44

41

82

164

410

46

39

78

157

391

48

37

75

150

375

50

36

72

144

360

52

35

69

138

346

54

33

67

133

333

56

32

64

129

321

58

31

62

124

310

60

30

60

120

300

62

29

58

116

290

64

29

56

112

281

66

29

54

109

273

68

28

53

106

265

70

26

51

103

257

72

25

50

100

250

74

24

48

97

243

76

24

47

95

237

78

23

46

92

231

80

22

45

90

225

Table 12: Input Rate

more than 0.3 inch w.c. If measured input rate is

still less than 98% of rated input:

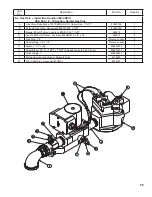

i.

Remove Main Burners per procedure in

Section IX: Service.

ii.

Remove gas orifices. Drill one (1) drill size

larger (drill size is stamped on orifice, or see

Key No. 4E).

iii.

Reinstall gas orifices and main burners.

Measure input rate.

6. Recheck Main Burner Flame.

7. Return other gas-fired appliances to previous

conditions of use.

N.

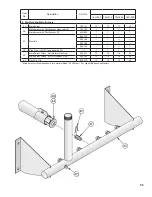

Adjust gas input rate to boiler.

LP/Propane.

1. Set thermostat to highest setting.

2. Adjust tank regulator for gas valve inlet pressure of

13.5 inches w.c. or less.

3. Gas valve has step opening regulator which initially

Summary of Contents for 16H-340

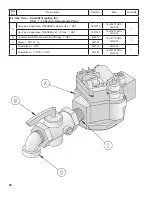

Page 13: ...13 Figure 8 Jacket Assembly ...

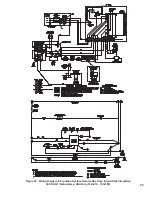

Page 14: ...14 Figure 9 EP CSD 1 Control Installation ...

Page 16: ...16 Figure 11 Main Gas Piping Intermittent Ignition EI ...

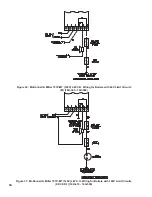

Page 17: ...17 Figure 12 Schematic Pilot Piping Honeywell EI USA ...

Page 18: ...18 Figure 15 Schematic Gas Piping EP CSD 1 Control System 16H 410 16H 505 ...

Page 37: ...37 Figure 41 Operating Instructions EI ...

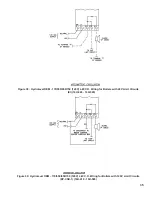

Page 47: ...47 Honeywell EI Trouble Shooting Guide ...

Page 48: ...48 THIS PAGE LEFT BLANK INTENTIONALLY ...

Page 58: ...58 ...

Page 60: ...60 ...