36

WARNING

Completely read, understand and follow all

instructions in this manual before attempting

start-up.

A.

Safe operation

and other performance criteria were met

with the gas manifold and control assembly provided

on boiler when boiler underwent tests specified in

American National Standard for Gas-Fired Low-

Pressure Steam and Hot Water Boilers

, ANSI Z21.13.

B.

Check Main Burners.

Main burners must be properly

located on support bracket in Base Rear Panel, seated

on Main Burner Orifices, and secured with hitch pin

clips.

C.

Verify that the venting, water piping, gas piping

and electrical system

are installed properly. Refer to

installation instructions contained in this manual.

D.

Confirm all electrical, water and gas supplies

are turned off at the source and that vent is clear of

obstructions.

E.

FILL ENTIRE HEATING SYSTEM WITH WATER

and vent air from system. Use following procedure on

a Series Loop or multi-zoned system installed as per

Figure 21 to remove air from system when filling.

WARNING

The maximum operating pressure of this boiler is

50 psig. Never exceed this pressure. Do not plug

or modify pressure relief valve.

1. Close full port ball valve in boiler supply piping.

2. Isolate all zones by closing zone valves or shut-off

valves in supply and return of each zone(s).

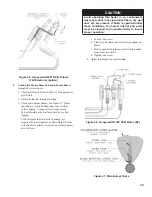

3. Attach a hose to the vertical purge valve located

prior to the full port ball valve in the system supply

piping. (Note - Terminate hose in five gallon bucket

at a suitable floor drain or outdoor area).

4. Starting with one circuit at a time, open zone valve

or shut-off valve in system supply and return piping.

5. Open purge valve.

6. Open fill valve (Make-up water line should be

located directly after full port ball valve in system

supply piping between air scoop and expansion

tank).

7. Allow water to overflow from bucket until discharge

from hose is bubble free for 30 seconds.

8. Close the open zone valve or shut-off valve for the

zone being purged of air, then open the zone valve

or shut-off valve for the next zone to be purged.

Repeat this step until all zones have been purged. At

completion, open all zone valves or shut-off valves.

VIII. System Start-Up

9. Close purge valve, continue filling the system

until the pressure gauge reads the desired cold fill

pressure. Close fill valve.

(Note - If make-up water line is equipped with

pressure reducing valve, adjust pressure reducing

valve to desired cold fill pressure. Follow fill valve

manufacturer’s instructions).

10. Open isolation valve in boiler supply piping.

11. Remove hose from purge valve.

F.

Confirm that the boiler and system have no water

leaks.

G.

Prepare to check operation.

1. Obtain gas heating value (in Btu per cubic foot)

from gas supplier.

2. Connect manometer to pressure tap on gas valve.

Use 1/8 NPT tapping provided.

3. Temporarily turn off all other gas-fired appliances.

4. Turn on gas supply to the boiler gas piping.

5. Confirm that the supply pressure to the gas valve is

14 in. w.c. or less.

6. Open the field installed manual gas shut-off valve

located upstream of the gas valve on the boiler.

7. Using soap solution, or similar non-combustible

solution, electronic leak detector or other approved

method. Check that boiler gas piping, valves, and

all other components are leak free. Eliminate any

leaks.

8. Purge gas line of air.

H.

Follow Lighting or Operating Instructions

to place

boiler in operation. Refer to label on inside of Front

Removable Panel or appropriate Figure as listed in

Table 11.

DANGER

Do not use matches, candles, open flames or

other ignition source to check for leaks.

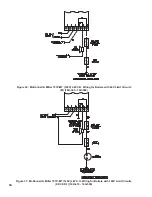

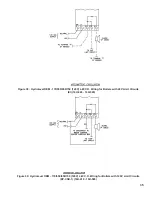

Ignition System

Lighting and

Operating

Instructions

Pilot Flame

Illustration

Honeywell EI

Figure 41

Figure 45

EP-CSD-1

Figure 43

Figure 46

Table 11: Lighting and Operating Instructions

Summary of Contents for 16H-340

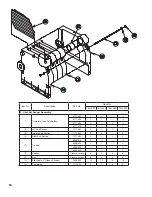

Page 13: ...13 Figure 8 Jacket Assembly ...

Page 14: ...14 Figure 9 EP CSD 1 Control Installation ...

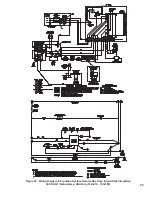

Page 16: ...16 Figure 11 Main Gas Piping Intermittent Ignition EI ...

Page 17: ...17 Figure 12 Schematic Pilot Piping Honeywell EI USA ...

Page 18: ...18 Figure 15 Schematic Gas Piping EP CSD 1 Control System 16H 410 16H 505 ...

Page 37: ...37 Figure 41 Operating Instructions EI ...

Page 47: ...47 Honeywell EI Trouble Shooting Guide ...

Page 48: ...48 THIS PAGE LEFT BLANK INTENTIONALLY ...

Page 58: ...58 ...

Page 60: ...60 ...