32

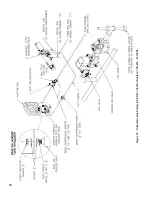

2. Electronically Supervised Intermittent Ignition

(EP-CSD-1) Sequence of Operation

a. Normal Operation

i.

Thermostat or operating control calls for

heat.

ii.

Terminal #6 of RM7890A Burner Control

is energized, initiating a microcomputer

monitored circuit test.

iii.

The pilot valve (terminal 8) and ignition

transformer (terminal 10) are energized.

The pilot valve opens and the ignition

electrode sparks, igniting the pilot.

iv.

After the pilot flame is proven, the ignition

terminal (10) is de-energized and the main

valve terminal (9) is energized, allowing

main gas flow and ignition of main burners.

“Main” gas light will be illuminated.

v.

When the call for heat ends, terminal #6

is de-energized, extinguishing the pilot

and main flames. “Main” gas light is de-

energized.

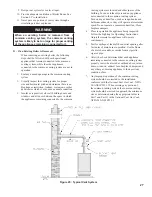

b. Safety Shutdown

i.

Limit: Automatically interrupts main burner

operation when water temperature exceeds

set point. Maximum allowable temperature

is 250°F. Circulator continues to operate

with call for heat. Normal operation

resumes when water temperature falls below

set point.

ii.

Blocked Vent Switch: Automatically

interrupts main burner operation when

excessive flue gas spillage occurs.

Circulator continues to operate with call for

heat. If blocked vent switch is activated,

do not attempt to place boiler in operation.

Correct cause of spillage and reset blocked

vent switch.

iii.

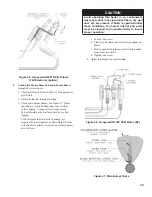

Flame Roll-out Switch: Automatically

interrupts main burner operation when

flames or excessive heat are present in

vestibule. Circulator continues to operate

with call for heat. Control is single use

device. If flame roll-out switch is activated,

do not attempt to place boiler in operation.

Correct cause of spillage and replace flame

roll-out switch.

iv.

RM7890A Burner Control: Automatically

interrupts main burner operation if a pilot

flame is not detected during the four or ten

second pilot flame establishing period. The

RM7890A will lockout or recycle based

on jumper settings. “Alarm” light will be

illuminated. Refer to instructions supplied

with RM7890A for additional control

information.

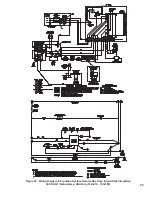

Summary of Contents for 16H-340

Page 13: ...13 Figure 8 Jacket Assembly ...

Page 14: ...14 Figure 9 EP CSD 1 Control Installation ...

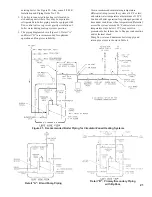

Page 16: ...16 Figure 11 Main Gas Piping Intermittent Ignition EI ...

Page 17: ...17 Figure 12 Schematic Pilot Piping Honeywell EI USA ...

Page 18: ...18 Figure 15 Schematic Gas Piping EP CSD 1 Control System 16H 410 16H 505 ...

Page 37: ...37 Figure 41 Operating Instructions EI ...

Page 47: ...47 Honeywell EI Trouble Shooting Guide ...

Page 48: ...48 THIS PAGE LEFT BLANK INTENTIONALLY ...

Page 58: ...58 ...

Page 60: ...60 ...