Viper Service Manual

Publication Number: 621260373SER

- 30 -

© 2008-2012, IMI Cornelius Inc.

When the daylight savings settings are complete, press the BACK button to save

the settings and return to the Select menu, shown in Figure 19.

Events Setup Menu

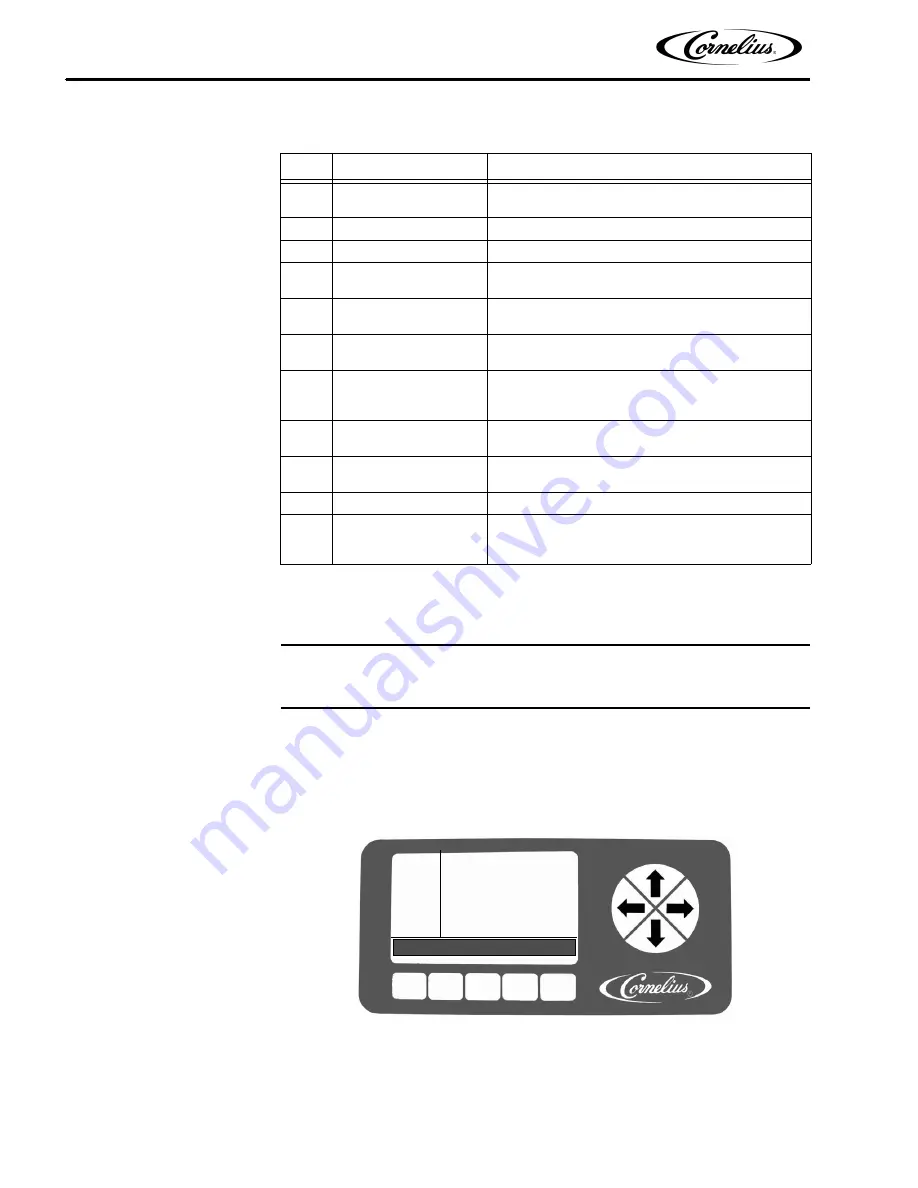

The Events Setup menu, shown in Figure 22, allows the user to set sleep periods

for the unit and to lock out the defrost cycle during peak busy times. Sleep periods

and defrost lockouts may be programmed for any day of the week or for all days of

the week, depending on business requirements. Button functions are described in

Table 15.

Figure 22. Event Setup Screen

Table 14

Step

Action

Procedure

1

Set daylight savings

time

Press DST button at the bottom of display to open

daylight savings time display, shown in Figure 21.

2

Select DST

Use the up and down arrows to select DST.

3

Set DST on

Use the + button to turn on daylight savings time.

4

Select SPRING

MONTH

Use up and down arrows to select SPRING

MONTH.

5

Set SPRING MONTH

Use the + or - buttons at the bottom of the display

to set the correct month.

6

Select SPRING

WEEK

Use up and down arrows to select SPRING WEEK.

7

Set SPRING WEEK

Use the + or - buttons at the bottom of the display

to set the correct week. The choices are 1, 2, 3 or

L.

8

Select FALL MONTH

Use the up and down arrows to select FALL

MONTH.

9

Set FALL MONTH

Use the + or - buttons at the bottom of the display

to set the correct month.

10

Select FALL WEEK

Use up and down arrows to select FALL WEEK.

11

Set FALL WEEK

Use the + or - buttons at the bottom of the display

to set the correct week. The choices are 1, 2, 3 or

L.

EVENT

SETUP

12:51P

MAR

04

DAY

SUN

SLEEP

10

:

00

PM

BACK

CLEAR

‐

+

WAKEUP

08:00

AM

DEFROST

LOCK

1:

05:15

PM

DEFROST

LOCK

2:

09:30

AM

DEFROST

LOCK

3:

‐‐‐‐‐‐‐‐‐‐‐‐