Non-Overhaul Removal and Replacement

Teledyne Continental Motors, Inc.

TM

10-26

IOF-240 Series Engine Maintenance Manual

29 November 2006

14.

Remove the rocker arms (20) and shafts (24) from the cylinder studs.

15.

Inspect the valve rocker shafts (24), thrust washers (23), and retainers (25).

16.

Withdraw all of the push rods (40) from their respective housings (35).

17.

Grasp each push rod housing (35) and push it inward toward the crankcase,

compressing the push rod housing spring (37); lift the cylinder end and remove the

push rod housing (35), springs (37), washers (38), and packing (39).

18.

Discard the springs (37) and packing (39).

19.

Using the appropriate wrenches, carefully remove flange nuts (45 and 46) from the

cylinder base flange.

20.

As the last pieces of fastening hardware are being removed, cradle the cylinder in

your arm to support the cylinder.

CAUTION: The piston will be damaged if allowed to drop as the

cylinder is withdrawn.

21.

While supporting the cylinder, carefully and slowly pull the cylinder outward in a

straight plane with one hand, keeping the other hand free to catch the piston as the

cylinder is withdrawn to prevent damage to the crankcase or cylinder.

22.

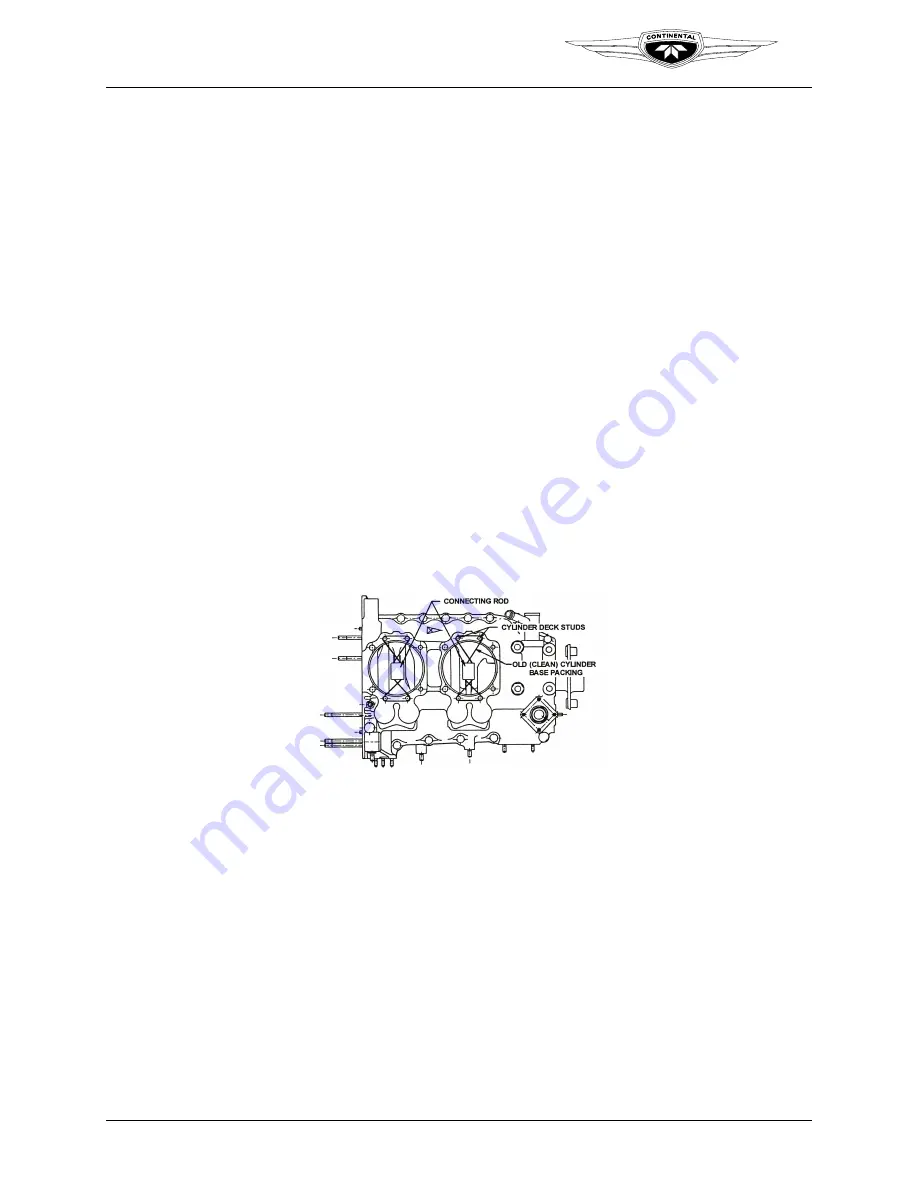

Remove the cylinder base packing (1). Install the old packing in a figure 8 pattern

(Figure 10-13) to support the connecting rod.

Figure 10-13.

Cylinder Base Packing Configuration on Connecting Rod Support

23.

Remove the piston pin (52) (Figure 10-12) and piston (53) from the connecting rod.

Inspect the piston pin (52). Remove and discard the piston rings (48 through 51).

24.

Remove and inspect the hydraulic tappets (47) from the crankcase tappet bores.

Identify the location from where the tappets were removed

since they must be re-

installed (if acceptable) in the same location

. Inspect the hydraulic lifters, lifter bores

and cam lobes for nicks, scratches, gouging, spalling or galling using the guidance in

Chapter 7. Replace hydraulic tappets which exhibit face or body wear exceeding 10%

of the surface area. If hydraulic tappets require replacement, inspect the cam lobes of

the associated valve for associated wear.

25.

When the cylinder is removed with the spark plugs installed, inspect the cylinder for

static leaks by filling the inverted cylinder bore with nonflammable solvent and check

for leaks at the static seal areas.