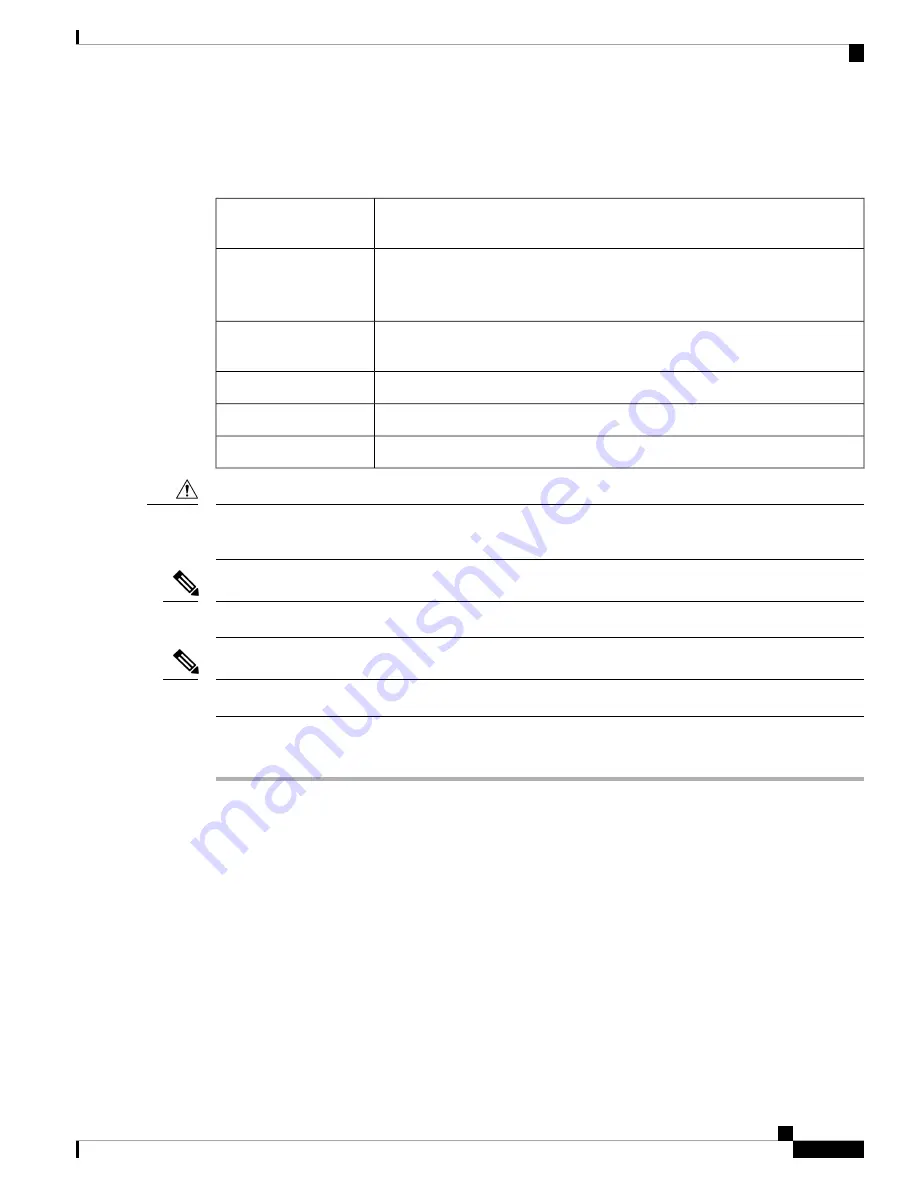

DLP-G821 Mounting the Bracket with Air Deflectors (Front-to-Side) on the ONS

15454 M6 Shelf for ETSI Rack Configuration

This task installs the bracket with air deflectors (front-to-side) on the ONS 15454

M6 shelf for ETSI rack configuration.

Purpose

• #2 Phillips Dynamometric screwdriver

• Medium slot-head screwdriver

• Small slot-head screwdriver

Tools/Equipment

NTP-G305 Unpack and Inspect the ONS 15454, ONS 15454 M2, and ONS 15454

M6 Shelves

Prerequisite Procedures

As needed

Required/As Needed

Onsite

Onsite/Remote

None

Security Level

Use only the fastening hardware provided with the ONS 15454 M6 to prevent loosening, deterioration, and

electromechanical corrosion of the hardware and joined material.

Caution

It is recommended to maintain a space of one RU between two chassis in a rack for cable management

Note

Hot and cold aisle airflow management must be planned for the installation.

Note

Procedure

Step 1

Place the right front air deflector flush against the right side of the chassis (see diagram below).

Installing the ONS 15454 M6 Shelf

43

Installing the ONS 15454 M6 Shelf

DLP-G821 Mounting the Bracket with Air Deflectors (Front-to-Side) on the ONS 15454 M6 Shelf for ETSI Rack Configuration