51-20

Page 38

All

EFFECTIVITY:

C I R R U S

A I R P L A N E M A I N T E N A N C E M A N U A L

M O D E L S R 2 0

15 Jun 2010

Type

P/N or Spec.

Cure Cycle

Structural Resin

or

Paste Adhesive

Repair System: MGS L418-Based

L418

H418

Initial

3 hours at 150°-210°F (66°-99°C)

or

5 hours at 125°-210°F (52°-99°C)

Post

10 hours at 175°-210°F (79°-99°C)

Structural Resin Repair System: MGS

L285-Based

L285

H287

Initial

1 hour at 150°-210°F (66°-99°C)

or

3 hours at 125°-210°F (52°-99°C)

Post

7 hours at 180°-210°F (82°-99°C)

Structural High Temperature Resin:

Hysol EA 9396-Based

a

9396-A

9396-B

Initial

30 mins at 125°-210°F (52°- 99°C)

or

24 hours at 65°-210°F (18°- 99°C)

Post

1 hours at 200°-210°F (93°- 99°C)

Structural Paste Adhesive Repair

System: PTM&W ES6292-Based

ES6292-A

ES6292-B w/ Beads

Initial

1 hour at 120°-210°F (49°- 99°C)

Post

5 hours at 180°-210°F (82°- 99°C)

Structural High Temperature Paste

Adhesive: Hysol EA 9395-Based

b

9395-A

9395-B

Initial

30 mins at 125°-210°F (52°- 99°C)

or

24 hours at 65°-210°F (18°- 99°C)

Post

1 hours at 200°-210°F (93°- 99°C)

Non-Structural Resin Repair System:

Epon-Based

Epon 862

Epicure 3234

Initial

24 hours at 65°-75°F (18°-24°C)

or

3 hours at 120°-210°F (49°-99°C)

or

1 hours at 150°-210°F (66°-99°C)

Post

2 hours at 150°-210°F (66°-xx°C)

Non-Structural Resin Repair System:

Epon-Based with Heloxy Dilutant

Epon 862

Heloxy 68

Epicure 3234

Initial

24 hours at 65°-75°F (18°-24°C)

or

3 hours at 120°-210°F (49°-99°C)

or

1 hours at 150°-210°F (66°-99°C)

Post

2 hours at 150°-210°F (66°-99°C)

Non-Structural Resin Repair System:

Derakane-Based

Derakane 470-36

Nuodex, Cobalt

Naphthenate, 6%

Luperox CU90

Initial

8 hours at 65°-75°F (18°-24°C)

or

1 hours at 150°-210°F (66°-99°C)

Post

24 hours at 65°-75°F (18°-24°C)

or

6 hours at 150°-210°F (66°-99°C)

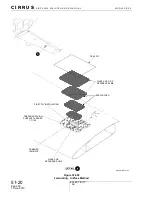

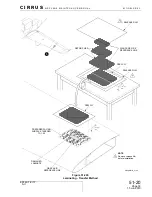

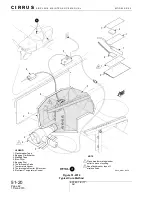

Figure 51-2011

Cure Temperatures and Times