51-20

Page 10

All

EFFECTIVITY:

C I R R U S

A I R P L A N E M A I N T E N A N C E M A N U A L

M O D E L S R 2 0

01 May 2012

(5)

Repair Surface Preparation

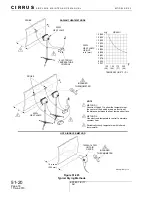

Generally, hand-sanding or a orbital type sander are the preferred methods of repair surface

preparation. Care must be exercised not to apply excessive pressure on the sander, which could

tear into the laminate. The grade of sanding paper is to be chosen to suit and give a smooth fin-

ish. Do not use grinders, air files, or other single-action tools as they tend to intensify pressure

and will rapidly remove paint and damage the underlying laminate.

To facilitate proper sanding depth and surface coverage, marking the composite repair area with

a permanent maker to act as a depth tracer is recommended.

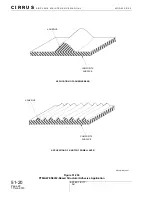

Remove dust and observe laminate surface frequently during the sanding procedure. If fiber

damage is apparent, stop sanding and repair the damaged area. When preparing peel ply sur-

faces, sand surface until the impression left from the peel ply is no longer visible. When prepar-

ing surfaces where no peel ply was present, such as barrier film, sand surface until no gloss is

visible. Replace or clean sandpaper often.

The repair surface must be free of EMM in an area equal to the size and shape of the largest

repair ply plus 0.5".

CAUTION:

Do not use chemical strippers to remove surface protection. Chemical strippers

may leave a residue and breakdown the epoxy resin.

Note:

To prevent possible re-contamination of the repair area, the repair must be done

immediately following repair surface preparation.

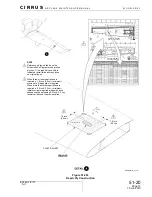

(a)

Acquire necessary tools, equipment, and supplies.

(b)

Remove damage from repair area.

(c)

Determine warp axis and draw 0° reference line so it intersects the center of the damage.

This line will later be used for positioning repair plies.

(d)

Mask off area surrounding repair with masking tape and paper. This area should include

the intended faying surface area plus at least 2 inches (50 mm).

(e)

If applicable, install backing plate.

(f)

For secondary bond damage, sand repair area:

Description

P/N or Spec.

Supplier

Purpose

Tape

-

Any Source

Masking.

Paper

-

Any Source

Masking.

Vacuum

-

Any Source

Cleaning.

Paint Brush

-

Any Source

Cleaning.

Permanent Marker

Depth tracer.

Sanding Pad

-

Any Source

Abrasion.

Aluminum Oxide Paper

(hand sanding)

60 to 80 grade

Any Source

Abrasion.

Orbital Sander

-

Any Source

Abrasion.

Aluminum Oxide Paper

(orbital sander)

120 to 180 grade Any Source

Abrasion.