C I R R U S

A I R P L A N E M A I N T E N A N C E M A N U A L

M O D E L S R 2 0

51-20

Page 19

All

EFFECTIVITY:

D. Repair Processes

(1)

Amine Blush Detection and Removal

CAUTION:

Special preparation may be required for surfaces repaired with epoxies using

polyamine hardeners such as Epon 862 or PTM&W ES6292. During the cure pro-

cess, amine blush, a thin, waxy film may form on the surface of the epoxy. This

film can greatly impair the strength of a repair bond.

Amine blush is a thin, waxy, soap-like film that forms on the surface of mixed epoxy resins that

use aliphatic amines - such as Epon 862 or PTM&W ES6292 - in the hardener. The blush film

begins to form on the surface of the adhesive immediately after being applied.

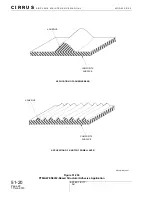

During a wet repair, in order to achieve a successful bond, the blush film must be broken when

the faying surfaces are pressed together. For this to happen, the adhesive applied to both faying

surfaces must be thick enough to be disrupted or "squish out".

Additional methods of eliminating amine blush are available; during the repair process; always

applying peel ply over the surface of the epoxy which will removed the film when the peel ply is

peeled from the cured epoxy, or remove the blush using a water wash.

To remove the blush using the water wash method, wash the surface with clean water and an

abrasive pad. Dry the surface with plain white paper towels to remove the dissolved blush before

it dries on the surface. After washing with the abrasive pad, the surface should appear dull. Sand

any remaining glossy areas.

(2)

MGS L418-Based Structural Adhesive Application

Application of structural adhesive is required for secondary bond repairs where the technician

must bond two pre-cured components together.

Note:

Nominal bondline thickness for structural repair is 0.060 +0.020/-0.055 inch

(0.152 +0.051/-0.140 cm) unless otherwise noted.

(a)

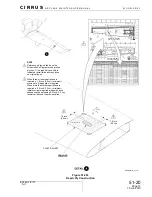

Acquire necessary tools, equipment, and supplies.

(b)

Prepare repair surface as necessary.

(c)

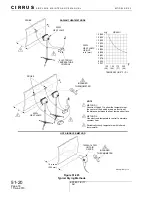

Pre-fit faying surfaces of parts to ensure the bond fixture used will bring the bonded sur-

faces into an allowable tolerance during adhesive curing.

(d)

Mix structural adhesive.

(e)

Prior to applying the bulk of adhesive, wet the faying surface by working a thin layer of

adhesive into the laminate substrate.

(f)

Apply a sufficient quantity of adhesive, determining the actual bond gap and width, so that

the joint will be completely filled over the faying surface width.

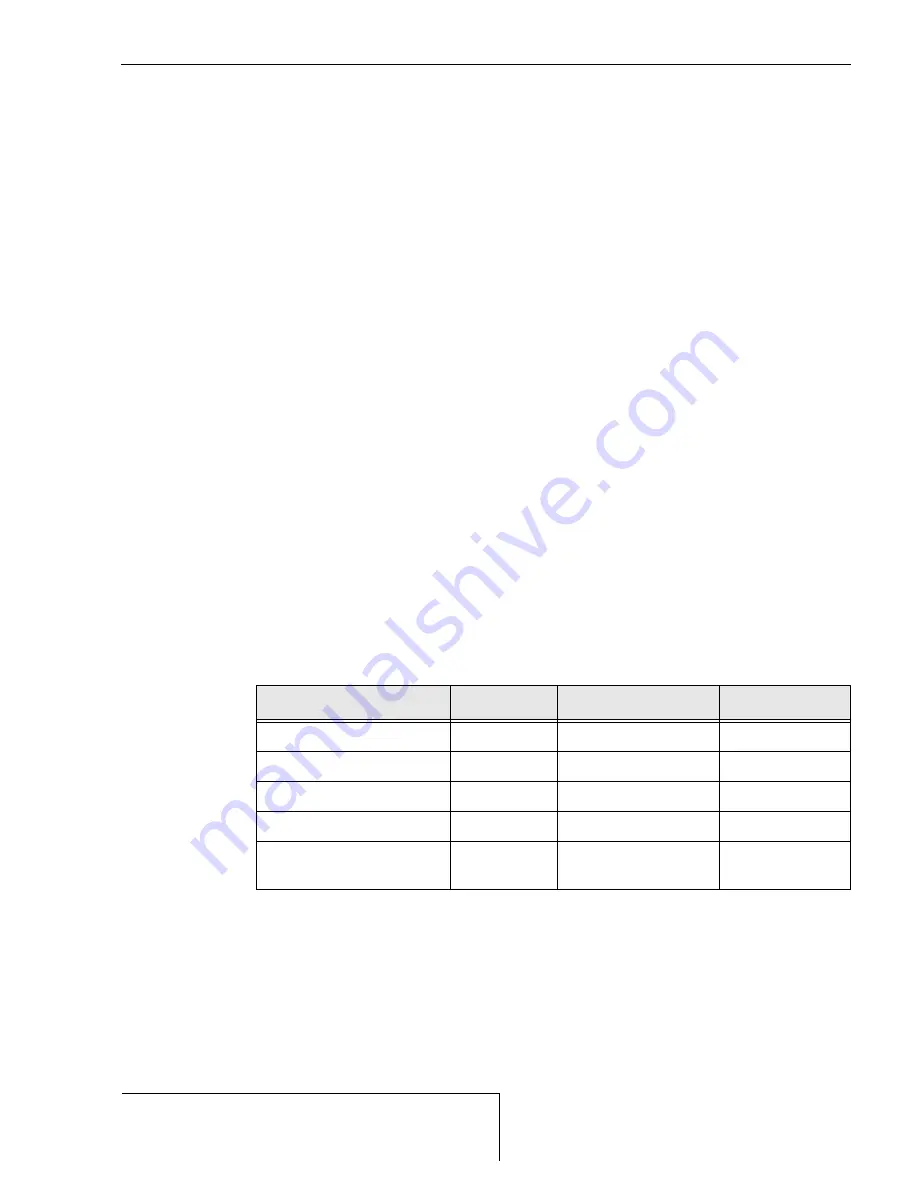

Description

P/N or Spec.

Supplier

Purpose

Wooden or Plastic Spatula

-

Any Source

Apply adhesive.

Cartridge or Extrusion Gun -

Any Source

Apply adhesive.

Bond Fixture (as necessary) -

Any Source

Bonding.

Clamps (as necessary)

-

Any Source

Bonding.

MGS L418-Based Structural

Adhesive

Core replacement.

15 Jun 2010