C I R R U S

A I R P L A N E M A I N T E N A N C E M A N U A L

M O D E L S R 2 0

51-20

Page 15

All

EFFECTIVITY:

Note:

When there is no risk of getting water trapped in open sandwich or the

structure, a thin layer of de-mineralized water may be sprayed on the sur-

face.

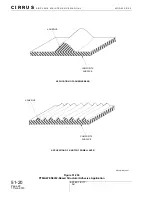

(d)

Perform Water Break Inspection.

1

Soak cloth with de-mineralized water and move cloth across repair surface to apply

a thin layer of water to the surface.

2

Inspect the wetted surface. When water forms a complete thin layer over whole of

the surface, and surface tension of the water does not cause water to form into

drops or beads, surface is clean.

3

Leave the water on the surface for 30 seconds. The water must remain as a com-

plete film over the surface for this period.

4

If the water separates or forms drops or beads within the 30 seconds, repeat solvent

cleaning procedure.

(e)

Repeat Procedure - Water Break Test until no contamination is noted on drying cloth.

(f)

Dry repair area.

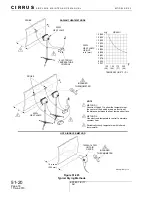

(9)

Drying Composite Structure

Because composites can trap water during service or repair, it is essential to thoroughly dry the

structure before a repair is performed. Trapped moisture can cause composite structure dis-

bonding or delamination both inside and outside the repair area due to due steam pressure gen-

erated during the cure cycle.

Since there is no practical method for quantifying the moisture content of a composite structure,

the structure should always be considered as saturated. Even when the composite structure is

visually dry it is necessary to perform a final drying before repairing. Visible liquid should first be

removed using absorbtion, vacuuming, and/or compressed air. Radiant heat or hot air may be

used as the final drying technique.

CAUTION:

Liquids that do not dry completely or leave a residue (jet fuel or hydraulic fluid for

example), must be cleaned and dried by some other method or the contaminated

part replaced entirely. Call Cirrus Design for disposition.

(a)

Dry any visible liquid as follows:

1

Acquire necessary tools, equipment, and supplies.

2

Solvent clean repair area.

3

Absorb visible liquid using cotton cloth.

CAUTION:

Do not allow flammable liquids or gases to enter the vacuum pump.

Ensure a vacuum system is approved for flammable liquid removal is

used.

4

If necessary, use vacuum to remove liquid from affected areas.

Description

P/N or Spec.

Supplier

Purpose

Cotton Cloth (clean, lint free) -

Any Source

Liquid removal.

Vacuum

-

Any Source

Liquid removal.

Dry Compressed Air

-

Any Source

Liquid removal.

15 Jun 2010