58

gaSteam cod. +030221930 rel. 5.3 - 06.06.2005

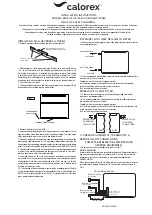

controller

remote causes

solution

action

reset

alarm

relay

H

terminal CAREL

(once having tried the suggestion,

Humivisor

if the problem persists, contact

the CAREL service department)

E503

the PTC probe in the flue

• switch the machine off, check the

total

power

active

has measured an over

level of the water, clean the boiler

shut-down

OFF

temperature

and the exchanger

E504

low water level in the boiler

• check the correct supply of water

total

power

active

or level control fault

to the boiler;

shut-down

OFF

• turn the machine off and clean:

the boiler, the level control and

the fill solenoid valve

E505

high conductivity of the

• turn the machine off and clean the

total

power

active

supply water

water conductivity measuring

shut-down

OFF

electrodes;

• if the problem persists, change

the source of the supply water

or install a suitable treatment

system (demineralisation,

even partial);

• the problem will not be resolved

by softening the supply water

E511

autotest failed; probable

• make sure that the machine is

humidifier

manual

active

problems in: supply water,

receiving water (1 to 8 bar,

disabled

level control or water drain

0.1 to 0.8 MPa, 14.5 to 116 psi);

• make sure that the machine

drains the water;

• switch the machine off and

clean the level control and the

fill valve, the pump and the

drain filter

E513

electrical power not

• check the gas pressure;

humidifier

manual

active

available; on machine

• check the operation of the

disabled

start-up no steam is

blower, the flue and the

produced or the water is

air outlet

not pre-heated

gaSteam 90

burner fault, fume

• burner flame

humidifier

manual

ON

exhaust or air inlet

malfunction;

disabling

(button 3

obstructed; gas cock

check the connection

fig.6.3.1)

E514

no water

• check that the supply pipe from

humidifier

manual

active

the water supply to the humidifier

disabled

and the internal pipe is not

blocked or choked and that the

pressure is sufficient (1 to 8 bar,

0.1 to 0.8 MPa, 14.5 to 116 psi);

• check the operation of the

fill solenoid valve;

• check that the steam supply

does not have to work against

excessive back-pressure,

preventing the flow of water into

the boiler due to gravity;

• check that the steam supply

pipe is not choked or that there

are no pockets of condensation

E515

foam in the boiler

• foam is usually due to the presence

warning-

manual

not

during boiling

of surfactants in the water

active

(lubricants, solvents, detergents,

water treatment or softening agents)

or an excessive concentration of

dissolved salts. Drain the water

supply line;

• clean the boiler