CDE360 Vector Control AC Drive Chapter 3 Mechanical and Electrical Installation

-

19

-

Chapter 3

Mechanical and Electrical Installation

3.1 Mechanical Installation

3.1.1 Requirements of Installation Environment

Item

Requirements

Item

1

Good ventilation.

5

Free from direct sunlight.

2

Ambient temperature: -10

℃

~

40

℃

.

6

Free from combustible, corrosive gas and liquid.

3

Free from high temperature, humidity (less

than 95%RH), no rainwater or other liquid drip.

7

Free from dust, oil dirt, floating fiber and metal powder.

4

Free from combustible objects, such as woods.

8

The installation base is stable with no vibration.

9

Free from magnetic interference.

3.1.2 Installation Direction and Clearance

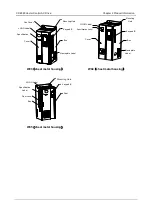

To ensure the heat dissipation of the product, please install the product vertically according to the

following figure and never invert the installation.

When the installation is in the cabinet, try to use the mode of side-by-side installation. At the same

time, to facilitate the heat dissipation, you should ensure that there is enough space around.

B

B

A

A

≥100mm

Single unit mode Up and down mode

Figure 3- 1 CDE360 installation diagram

Table 3- 1 The dimension size of the installation clearance

AC drive power class

(

kW

)

Installation size

(

mm

)

A

B

≤ 15

≥ 30

≥ 100

18.5

~

30

≥ 50

≥ 200

≥ 37

≥ 300

Remarks during the mechanical installation:

1) Please install the AC drive vertically. If there are several AC drives in the cabinet, try to use the

mode of side-by-side installation. When the cooling space can be guaranteed, please consider

the cooling requirements of other components.

2) As for the installation clearance, please refer to Table 3-1.

3) For occasions which have upper and lower installation, please refer to Figure 3-1 and install the

insulation guidance plate.

4) Please use the installation holder which contains incombustible materials.

5) For occasions which have metal powder, it is suggested that the heat sink is installed outside the

cabinet.

Guide plate